Temperature probes

Flow probe length

Return probe length

Probe type

Working temperature range limits

Temperature difference limits

Measurement sensitivity

Flow meter

Dimensions/Connection

Body

Type of hydraulic connection

Nominal pressure

Max. temperature of the medium

Mounting

Pulse output

Permanent flow rate

Minimum flow rate

Maximum flow rate

Electric supply

Microprocessor calculator unit

Metrological specifications

Accuracy class

Centralised transmission

Ambient temperature range limits

Ambient classification

Energy unit of measurement

Electric supply

Protection class

Pulse inputs

Technical specifications

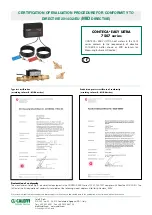

in compliance with EN 1434-1 - MID 2014/32/EU

class 2

according to M-Bus/ MODBUS RTU protocol on RS-485

5–45

MID 2014/32/EU E1-M1

8-digit display

24 V (+10 % / -5 %) (ac) - 1 W - 50 Hz

in accordance with DIN 40050: IP 54

class IB in accordance with EN 1434-2

1,9

1,9

NTC

10–90 (HEATING) - 2–25 (COOLING)

3–80 (HEATING) - 3–20 (COOLING)

≤

0,05

bar

°C

l/h

l/h

l/h

°C

kWh

PN

Q

p

Q

i

Q

s

m

m

°C

K

°C

90

preferably horizontal

class OA-OC in accordance with EN1434-2

see table 1 and 2

see table 1 and 2

see table 1 and 2

lithium battery, life 12 years

p

Code

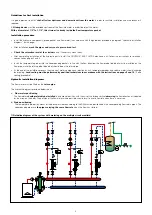

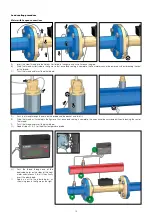

The CONTECA

®

heat meter is supplied with accessories for installation, probes positioning and subsequent lead sealing.

Code

DN

G

F

E

C

A

B

D

DN

A

C

B

D

PN

PN

2 x Y-pockets

(the flow pocket is fitted with a strainer mesh)

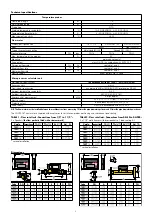

TABLE 1 - Flow rate limit - Connections from 1/2” to 1 1/2”:

Code

Connections

Code

Connections

2 x 1/2” weld sleeves with brass pocket to 1 lead sealing kit

* vertical installation

* vertical installation

TABLE 2 - Flow rate limit - Connections from DN 50 to DN 200:

1000

100

DN 125

100

1500

150

DN 150

100

2500

250

100

150

250

DN 200

100

100

Q

s

Q

s

7507

04

7507

05

7507

06

7507

07

7507

08

7507

09

7507

10

7507

11

7507

12

7507

13

7507

14

7507

15

Q /

p

100*/250

100*/250

p

Q /

p

Dimensions

2

Flanged EN 1092-1

Male thread ISO 228

Brass

DN 125–DN 200

1/2”–1 1/2”

DN 50–DN 100

Steel P235GH

PN 16

PN 16

PN 25

N.B. The flow meter must be installed between two rectilinear sections, measuring 10 times the pipe diameter upstream and 3 times the pipe diameter downstream.