25

Pouring the Deck

It is recommended that all electrical hook ups and all plumbing be completed

before pouring the concrete. Make certain all electrical inspections on

lights, bonding and all other electrical work have been completed and

checked off by the local inspectors prior to proceeding with your concrete

or finish work. It is a good idea to run the spa for at least 24 hours before

pouring the concrete to insure there are no leaks. We understand you

want to enjoy your spa now, but a 24-hour period with your spa running will

let you know of any problems before they will be extremely hard to fix.

The type of decking you have selected will have determined the grade of

the spa. If you are pouring a regular deck up to the spas coping, then the

top of the coping should be 4” above the surrounding area. In either event,

it is recommended to dig out an area around the spa exposing the flange

of the coping and just under it. This is important, as concrete should be

packed under and over the flange of the spa, as the deck is poured. This

will lock the spa into the concrete and provide for a much stronger bond

of the spa to the deck. It will also eliminate cracking of the deck where it

meets the spa.

When setting your outside forms, remember you want any water from rain

or splash out to run off the deck, not into the spa. If your deck is going to tie

into an existing deck, than some type of drain system should be planned to

handle the run off. Proper drainage planning is very important.

An experienced concrete finisher should always be used when pouring

spa decks, especially when you are doing a cantilevered deck, as the

forms must be taken off at the proper time to allow finishing of the inside

of the form.

Summary of Contents for Avalon A726B

Page 1: ......

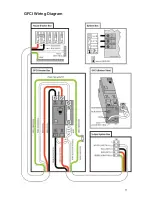

Page 13: ...11 GFCI Wiring Diagram...

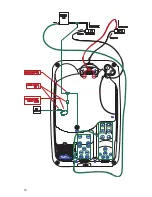

Page 17: ...15 RCD Wiring Diagram...

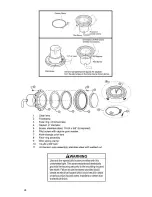

Page 18: ...16 Installing the In Ground Shell...

Page 20: ...18...

Page 26: ...24...

Page 31: ...29...