Instrument Comms Address

Configuring Instrument Comms Settings

7

This should also be done immediately after power-up, and

is only possible from the instrument front panel.

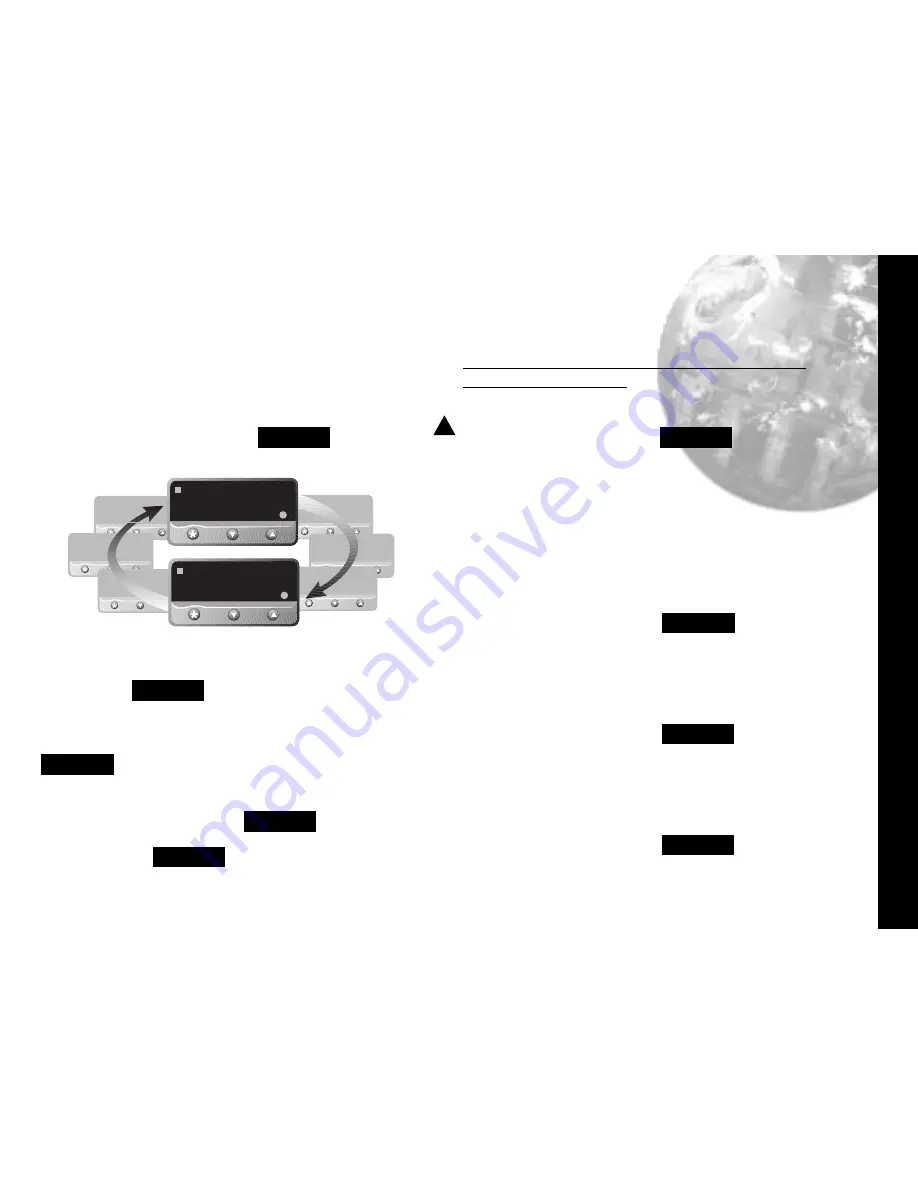

On power-up the controller will display the self test

sequence followed by Alternating

INPT

and

nonE

I

N

P

T

CAL

3300

I

N

P

T

CAL

3300

I

N

P

T

CAL

3300

N

O

N

E

CAL

3300

N

O

N

E

CAL

3300

N

O

N

E

CAL

3300

I

N

P

T

CAL

3300

N

O

N

E

CAL

3300

Note:

During the following procedure the display will revert

to alternating

INPT

and

nonE

after 60 seconds of

keying inactivity, but will retain any settings already

completed. Should this occur, or in the event of becoming

"lost" in the program, please start again from the alternating

INPT

and

nonE

display

To select Level C (communications settings)

Press

▼

once

display alternates

LEVL

and

5

Press and hold

✱

and press

▼

five times to reach

level C

display alternates

LEVL

and

C

!

Note: Level C is only visible when the comms interface

board is fitted to the unit

To set up Instrument comms address

Press

▲

once

display alternates

ADDR

and

0

Press and hold

✱

and press

▲

to index to chosen address

number

(1 to 247)

Note:

In the absence of any conflicting information the

following comms settings should be left as the default

values. (see details on page 6).

To read or adjust comms settings

Baud rate

Press

▲

once

display alternates

BAUD

and

9600

(Default setting)

Press and hold

✱

and use

▲

or

▼

keys to select preferred

value

Data format

Press

▲

once

display alternates

DATA

and

18n1

(Default setting)

Press and hold

✱

and use

▲

or

▼

keys to select preferred

setting (see table page 6)

Debug setting

Press

▲

once

display alternates

DBUG

and

oFF

(Default setting)

Press and hold

✱

and use

▲

key to select

on