12

13

4

Loading Material

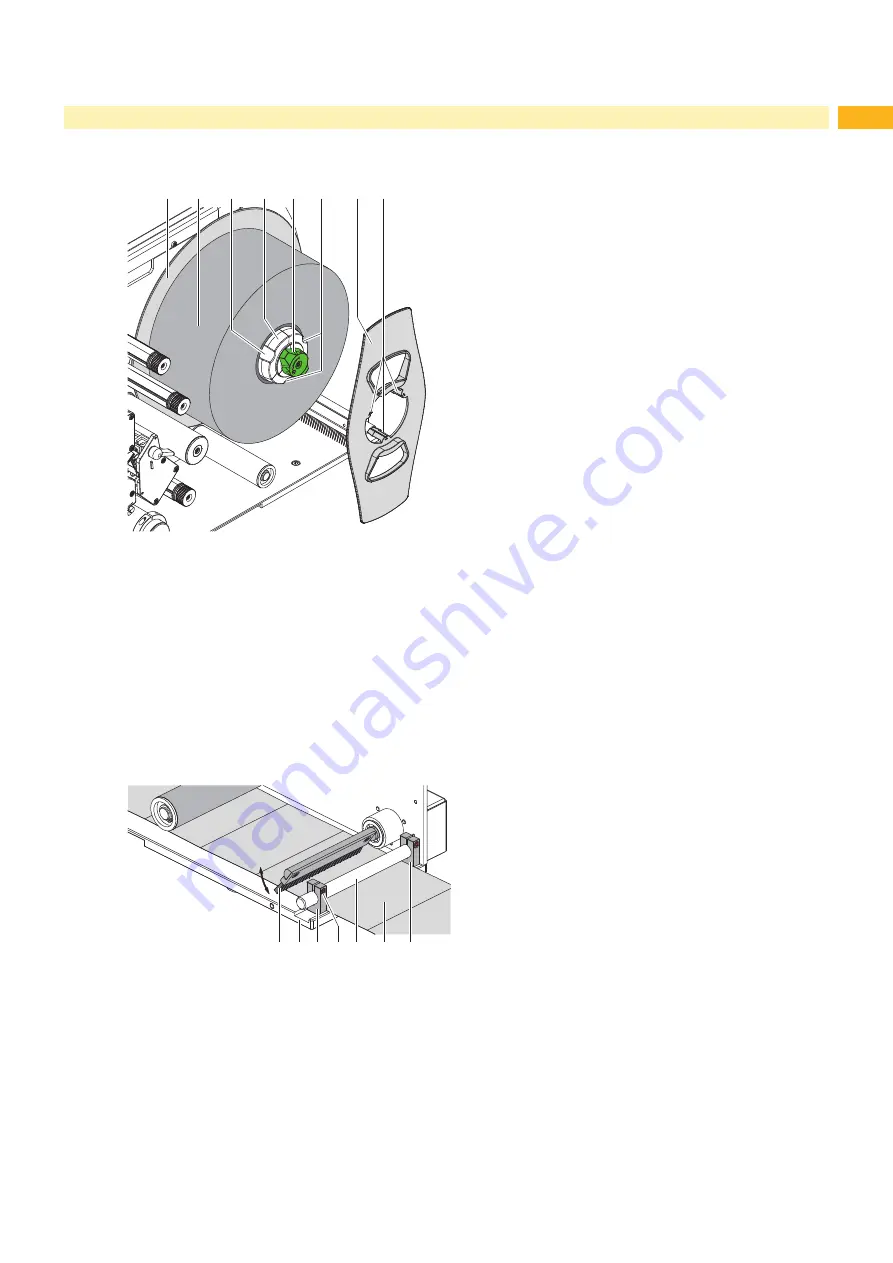

4.1.2 Positioning the Label Roll on the Roll Retainer

1

2

3

4

3

6 7

5

Fig. 7

Loading labels from roll

1. Turn knob (5) clockwise to release the roll retainer (4).

2. Remove the margin stop (6) from the roll retainer.

3. Load label roll (2) on the roll retainer (4) in such a way, that the labels are visible from above after unrolling.

4. Slide the roll against the wall plate (1).

5. Guide the latches (7) of the margin stop (6) into the grooves (3) of the roll retainer (4) and push the roll retainer

against the label roll (2).

6. Turn knob (5) counterclockwise to tighten the label roll and the margin stop on the roll retainer.

4.1.3 Loading Fanfold Labels

1

3 4

2

5

6 7

Fig. 8

Loading fanfold labels

1. Loosen screw (4) and slide guide (3) to the outermost position.

2. Swing brush (1) upwards.

3. Place the fanfold labels behind the printer.

4. Insert the labels (6) between baseplate (2) and axle (5) and feed the labels below the brush (1) to the print units.

5. Push the labels to the inner guide (7).

6. Slide the outer guide (3) against the labels and tighten screw (4).

7. Swing brush downwards (1).