UK

5

moves

hardness

from the water.

ºdH

is a term indicat-

ing the hardness of

the water and the

amount of dis-

solved salts in the

water. The lower

the number, the

softer water

3.

POSITIONING OF THE

PLANT

The plant must be placed in a

non-freezing environment on a

level foundation, so that the

water in the reservoir tank (op-

tion) does not overflow when the

tank is full.

The foundation must be able to

tolerate a weight load of 200 kg

in total which is the approxi-

mate weight of the RO plant in

operation. However, remember

to take into account the weight

of the softening unit and the

reservoir tank!

The max. outside measures of

the RO plants are WxDxH:

720 x 720 x 1690 mm, but

when positioning the plant you

must take into account that a

softening unit (option) and pos-

sibly a reservoir tank (option)

have to be installed too.

You have to allow for 1000 mm

extra height in order to be able

to take out the plant mem-

branes.

Also, there has to be made

room on the left side of the plant

for the water installation, espe-

cially the outlet hose from the

plant must be considered: The

hose may never be bent!

Positioning of plant must be in

such a way that the air intake at

the top of the pump never be-

comes covered.

Furthermore, there are readings

that have to be performed on

the front of the plant, e.g. flow

meter and possible alarm in

case of lacking water pressure.

Consequently the front must not

be covered up, but should al-

ways be visible.

In case of a stoppage, situations

may arise where the level in the

reservoir (option) overflows.

Therefore, there shall always be

a drain in close proximity of the

plant, placed in such a way that

the overflowing water does not

cause any damage.

If there is no floor drain which

has been dimensioned to the

full capacity of the RO unit

near the plant, installing the

plant is at your own risk.

4.

WATER QUALITY

The feed water, which is to be

treated in the BWT PERMAQ

®

Pro 2000 plant, must be sof-

tened drinking water quality

with maximum 500 mg/l TDS.

Max. temperature: 35 °C. The

plant is adjusted at 10 °C in our

factory.

The feed water may maximum

contain:

* Hardness:

0.5 °dH (obtain

Able by installation a soften-

ing unit (option))

* Fe:

0.05 mg/l

* Mn:

0.02 mg/l

* Cl:

0.1 mg/l

* Turbidity: 1.0 NTU

* SDI:

3.0 %/min

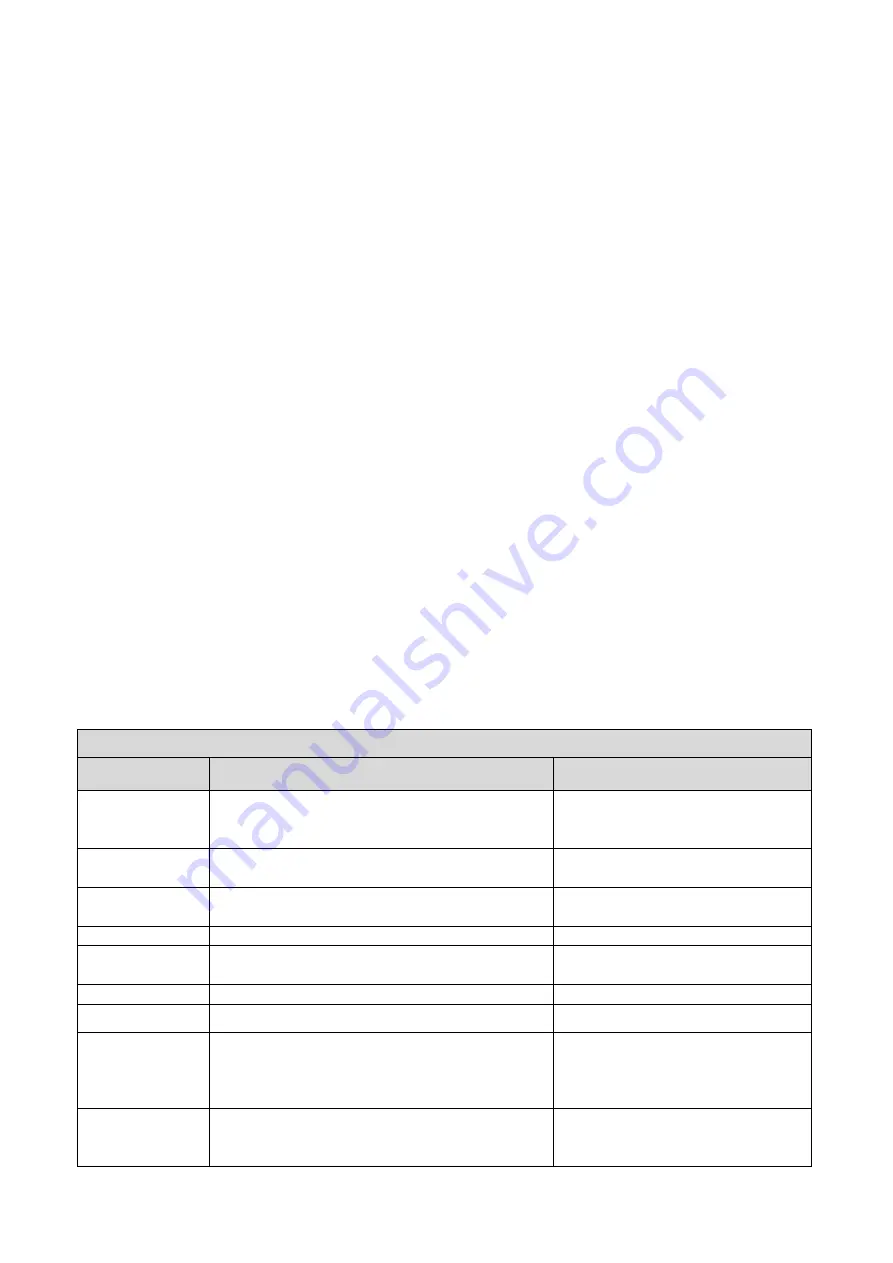

Water quality (contact BWT for technical advice)

Content

Symptom

Preventive action

TOC, BOC and

COD

Can cause slimy as well as firm hard film.

Can in some cases be micro-filtrated

or removed by means of a carbon

filter.

Iron, Manganese

(ocher)

Precipitation of iron gives a reddish-brown film and

precipitation of manganese gives a black deposit.

Sand filter – oxidation, softening,

greensand.

Calcium, magne-

sium (hard water)

The membrane scales.

Softening, antiscalant.

Silica

The membrane scales.

Antiscalant.

SDI (silt)

The membranes gets clogged.

Microfiltration (absolute), ultrafiltra-

tion, flocculation.

Oil

The membrane is greasy from oil.

Carbon filter.

Particles

The membrane gets clogged due to hard deposits.

Microfiltration.

Chlorine, pesti-

cides, organic

solvents

Membrane deformed. Permeate capacity and quali-

ty changed and cannot be CIP-cleaned back to the

original capacity. The deformation is not visible.

Free chlorine shall be removed by

active carbon filter and chemical

cleaning, either with Thiosulphate or

sulphite.

Bacteria

Membrane is clogged by slime.

Chlori de-chlorination, UV,

micro-filtration 0.2 µS/cm and ultra-

filtration.

Summary of Contents for PERMAQ PRO 2000

Page 2: ...UK 2...

Page 11: ...UK 11 Alarm Transport pump 9 2 4 Indication Level low 9 2 5...

Page 19: ...UK 19 13 1 P I Diagram...

Page 20: ...UK 20 13 2 Layout Drawings...

Page 21: ...UK 21 13 3 Wiring Diagram...

Page 22: ...UK 22...

Page 23: ...UK 23...

Page 24: ...UK 24...

Page 28: ...UK 28 13 7 Spare Parts Drawing...