UK

15

10.

TECHNICAL SPECIFICATION

10.1

Technical specifications

BWT PERMAQ

®

Pro 2000 series

Signature

Description

Type/data

P1a

High-pressure pump

2,2 kW, 4,45A

P1b

High-pressure pump

4,0 kW, 7,9A

P1c

High-pressure pump

4,0 kW, 7,9A

P2 (option)

CIP pump

0,85 kW, 4,5A

P3a (option)

Transport pump

0,85 kW, 4,5A

P3b (option)

Transport pump

1,2 kW, 3,0A

P5 (option)

Antiscalant pump

0,017 kW, 0,5A

P6 (option)

Pressure booster pump

0,5k W, 3,0A

FI 1A

Flow meter (permeate)

Ø40 PVC

FI 1B

Flow meter (permeate)

Ø63 PVC

FI 2 (option)

Flow meter (concentrate)

Ø32 PVC

PI 1

Manometer

0-40 Bar, ¼”

V1

Ball valve (control)

Brass

V2

Needle valve (recirculation)

Brass

V3

Needle valve (concentrate)

Brass

V4

Ball valve (check valve)

PVC

V5 (option)

Needle valve (mixing)

Brass

V7 (option)

Ball valve (CIP)

Brass

V8 (option)

Ball valve (CIP)

Brass

V9 (option)

Ball valve

(preparation for CIP)

Brass

V10 (option)

Ball valve (CIP)

Brass

Y1

Solenoid valve NC (raw water)

POM

Y2 (option)

Solenoid valve NC (quality flush)

POM

Y3 (option)

Solenoid valve NO (quality flush)

POM

Y5 (option)

Solenoid valve NC

POM

PS 1

Pressure switch NO

¼” 0,5 Bar

PS3a (option)

Pressure switch NC

¼” -0,2 to 8 Bar

PS3b (option)

Pressure transmitter

0-6 Bar

PS 6 (option)

Pressure switch NC

(pressure booster pump)

¼” -0,2 to 8 Bar

FS 5 (option)

Flow switch (antiscaling)

EPDM

QIS 1 (option)

Conductivity meter

½” connection for sensor

Summary of Contents for PERMAQ PRO 2000

Page 2: ...UK 2...

Page 11: ...UK 11 Alarm Transport pump 9 2 4 Indication Level low 9 2 5...

Page 19: ...UK 19 13 1 P I Diagram...

Page 20: ...UK 20 13 2 Layout Drawings...

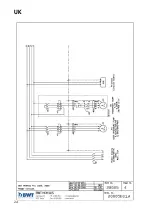

Page 21: ...UK 21 13 3 Wiring Diagram...

Page 22: ...UK 22...

Page 23: ...UK 23...

Page 24: ...UK 24...

Page 28: ...UK 28 13 7 Spare Parts Drawing...