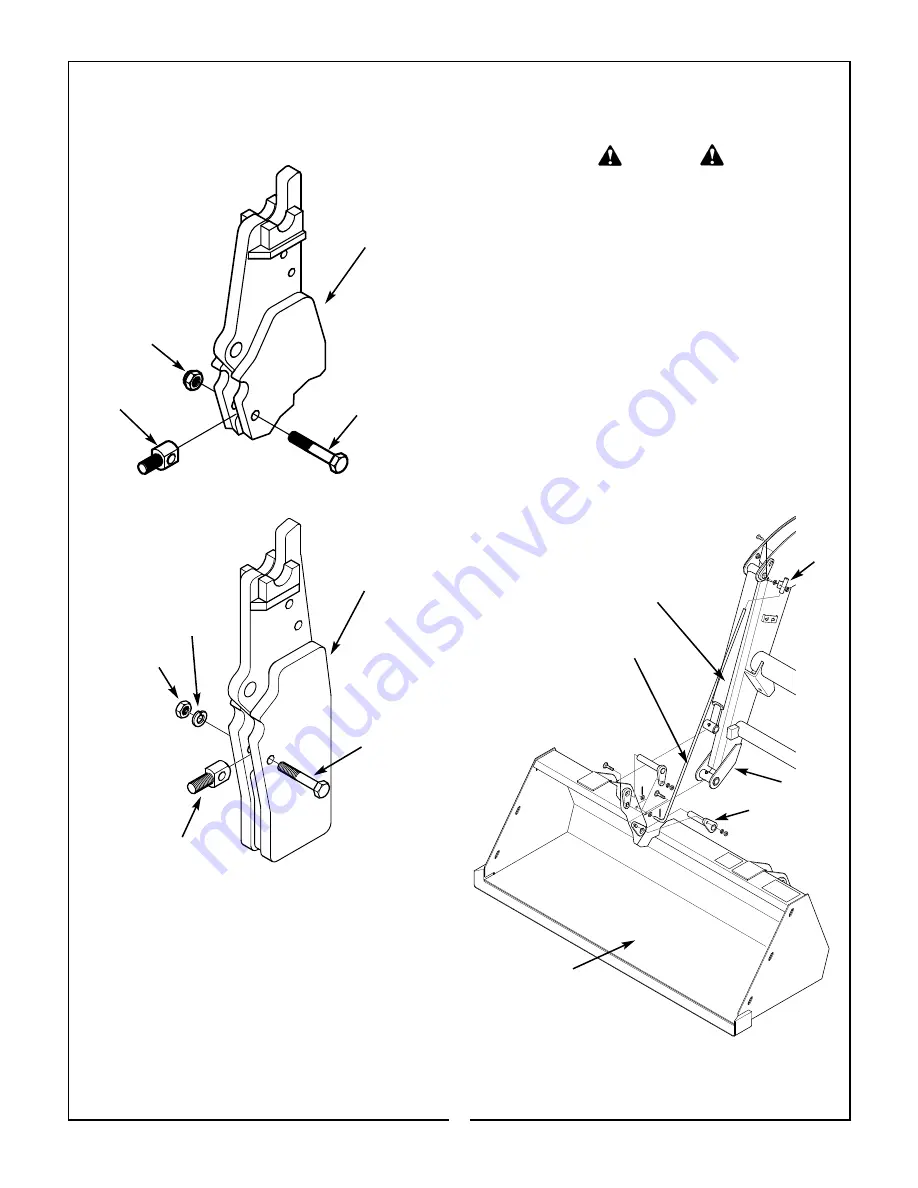

5-10 MOUNTING BRACKET EYEBOLT

Install eyebolt to each mounting kit center bracket

and secure with hardware. Figure 5-2.

Figure 5-2

5/8” Locknut

Mounting Kit

Center Bracket

CAUTION

LIFT AND SUPPORT ALL LOADER COM-

PONENTS SAFELY.

32

Eyebolt

5/8 x 3-1/2” Gr. 5

Hex Bolt

Verify that all mounting kit hardware has been

torqued as specified before installing loader.

A. Identify hardware size and grade.

B. Refer to Torque Specifications, page 34, and find

correct torque for your hardware size and grade.

C. Torque hardware to this specification unless oth-

erwise specified.

IMPORTANT

To prevent mounting kit hardware from loosen-

ing during loader operation always torque

mounting kit hardware to specified torque.

5-11 STANDARD BUCKET &

LEVEL INDICATOR ROD

A. Attach boom and hydraulic cylinders to bucket

using fasteners provided, as shown in Figure 5-3.

B. Place indicator rod through guide tube and posi-

tion as shown. (Level Indicator Rod and guide tube

may be mounted on the inside or outside of boom,

as desired.) Attach guide tube to mainframe using

1/4” bolt, flat washer and lock nut. Do not over-tighten

1/4” locknut as this will prevent guide tube from piv-

oting freely.

C. Attach lower end of indicator rod to bucket brack-

et using cotter pins and flat washers.

Support the loader by using a hoist. Refer to

Mounting The Loader, page 10, to install the loader

to mounting brackets previously installed on tractor.

M246

Figure 5-3

Standard Bucket

Level Indicator Rod

Guide

Tube

Boom

Hydraulic Cylinder

Bucket Pins &

Fasteners

M146

1/2” Lockwasher

1/2” Hex Nut

Eyebolt

1/2 x 3” Gr. 5

Hex Bolt

Mounting Kit

Center Bracket