Fig

37

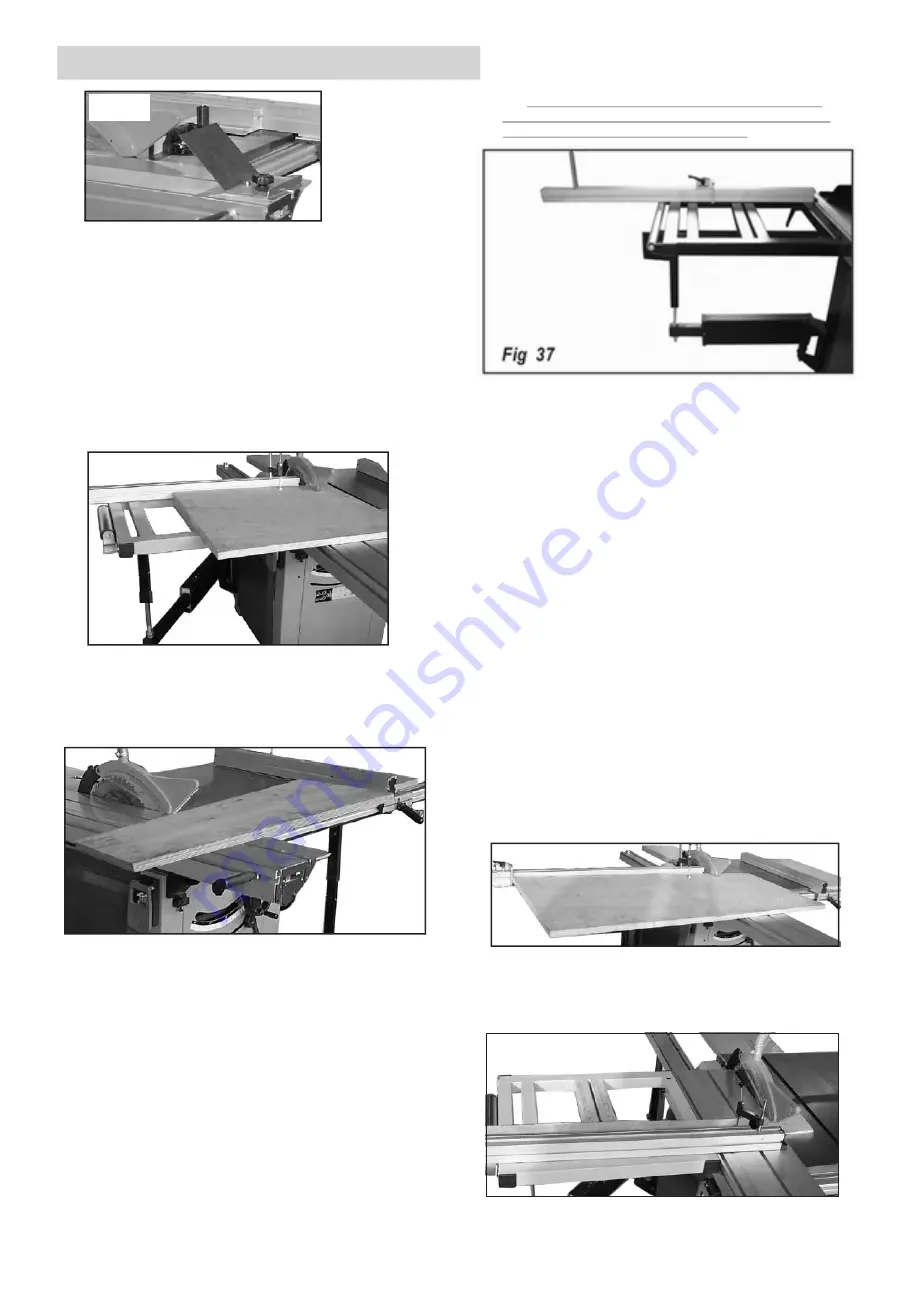

3.

Install the crosscut fence in the guide pin holes and

OPERATIONS

lock it in place with the knurled nut.

Note

First, drop the crosscut fence into the forward

guide pin hole, turn

the

"Z"lock

plate

to

align

the

fence,

then

tighten

the

knurled

nut

.

Your safety is important. To preventing work-piece kick-

back, slide the edge shoe into sliding panel when

needed.

The edge shoe can slide into the front or rear portion of

sliding panel.

Rip Cutting

The sliding panel saw has the capability of rip cutting

4.

Set either flip stop to the desired width-of-cut.

full size panels. The sliding panel removes the burden

of sliding a large and heavy panel over a stationary

5.

Load the workpiece onto the table saw.

table surface.

6.

Mount the hold down arm onto the stud and lock the

work-piece in place.

7.

Once all the necessary safety precautions have been

taken, perform the cutting operation.

Rip cutting using the traditional table saw

technique:

1.

Slide the crosscut table out of the way.

2.

Lock the sliding panel into a stationary position

.

3.

Position the rip fence to the desired width-of-cut.

This saw also has the capability of rip cutting smaller

4.

Once all the necessary safety precautions have been

boards, using the machine as a traditional table saw.

taken, load the workpiece onto the table saw and

Smaller, lighter boards are easier to slide across the

perform the cutting operation.

stationary cast iron table surface to the right of the saw

blade.

Crosscutting

With the crosscut fence mounted in the forward

position, the sliding panel saw has the capability of

crosscutting full size panels.

Determine which cutting operation will be best suited

for the workpiece to be ripped.

With the crosscut fence mounted in the rear position,

this machine also has the capability of crosscutting

To use the sliding table, read the instructions titled

smaller panels.

“Rip cutting with the sliding panel.”

To use the machine as a traditional table saw, skip

ahead to “Rip cutting using the traditional table saw

technique.”

Rip cutting with the sliding panel:

1.

Mount the crosscut table to the sliding panel.

2.

Slide and secure the crosscut table to the end of the

sliding table opposite the sliding table handle.

16

Fig

36

Fig

34

Fig

35

Fig

36

Fig

38

Fig

39

Summary of Contents for MJ12-1600

Page 1: ...Instruction Manual Sliding Panel Saw MODEL NO MJ12 1600 1800 2000...

Page 6: ...GETTING TO KNOW YOUR SLIDING PANEL SAW 5...

Page 21: ...LIMIT SWITCH ELECTRO MAGENETIC SWITCH LIMIT SWITCH ELECTRO MAGENETIC SWITCH...

Page 28: ...27 DIAGRAM A...

Page 29: ...28...

Page 30: ...29...

Page 31: ...30 DIAGRAM D...

Page 32: ...31...

Page 33: ...32 DIAGRAM F...

Page 34: ...33...

Page 35: ...34 DIAGRAM H...