See our catalog at

www.burrking.com

Contact us at

BURR KING MFG. CO., INC.

1220 TAMARA LANE

WARSAW, MO 65355

WWW.BURRKING.COM

(660) 438-8998

s

(800) 621-2748

FAX (660) 438-8991

April 2000

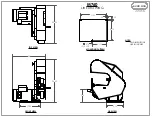

Instruction for aligning the idler wheels on model 760 belt grinders

When idler wheels are removed and/or replaced they must be installed such that they are in proper

alignment. Failure to properly align the idler wheels will result in premature failure of the wheels.

Premature failure will be evidenced by outer diameters being excessively worn such that the wheels lose

their factory crown, wear to a truncated form, or become out of balance. Misalignment results in wear that

is analogous to front tire wear when the front steering mechanism of an automobile is miss aligned. The

upper idler equates to the front wheels of the car. If either idler wheel is misaligned to each other or to the

contact wheel excessive, and irregular wear will occur.

The upper and rear idler wheels must operate in the same plane. This means that when they are correctly

aligned a plane passing through the radial center of the upper wheel will exactly pass through the radial

center of the rear wheel. Machines are shipped from the factory with wheels of the same width. In

example, the model 760 prior to mid 1999 was shipped with wheels that are 1.75 inches wide. Currently,

model 760 machines are shipped with wheels that are 2.0 inches wide. The 1.5 and 2.0 inch wheels may

be interchanged and/or mixed; however, if they are mixed their widths must be taking into account when

performing this alignment. The model 760 contact wheel may be 0.5, 1.5, or 2.0 inches wide. Likewise

the width of the contact wheel must be taken into account when performing this alignment.

Never perform maintenance or adjustments as described below on your model 760 without

first disconnecting the machine from its source of electric power. Failure to observe this

warning may lead to serious personal injury.

Procedure: (disconnect electric power and remove the abrasive belt)

1. Install the rear idler such that its inside-bearing surface is approximately 0.06 inches out from the

wheel support P/N 735. Secure the wheel with locking set screw P/N 25.

2. Install the upper wheel such that its inner bearing surface is approximately 0.06 inches out from its

bearing support P/N 714. Secure the wheel with locking set screw P/N 25.

3. Loosen the retaining nut P/N 22 that locks the upper idler wheel adjusting screw P/N 721. Using

screw P/N 721 adjust the upper idler wheel until a straight line representing the plane passing through

the center of the upper idler exactly passes through the center of the contact wheel. This line

represents the center of belt travel. Note: make certain that the bearing support is against the screw

end of P/N 721.

4. Project a line from the upper idler outside rim to the outside rim of the rear idler. Adjust the tracking

control P/N 711 until the wheels are exactly planar. That is their radial centers are aligned.

5. Repeat step 3 and 4 until both conditions are satisfied. That is the upper and rear idlers are aligned to

each other and both wheels are aligned to the contact wheel.

6. Tighten the locking nut on P/N 721.

7. Install a new abrasive belt. Roll the belt manually to assure that it will maintain coarse tracking. If the

belt does not track manually, repeat the prior steps until it does. If after repeating these steps the belt

still will not track the machine requires other maintenance and/or one or both idler wheels require

replacing. The wheels should be replaced in pairs.

8. Apply electric power to the machine and verify that the tracking control P/N 711 will sweep the belt

across the face of the contact wheel. At least ½ inch adjustment in both directions from center should

be possible.