65 Series Rotary Tiller

11

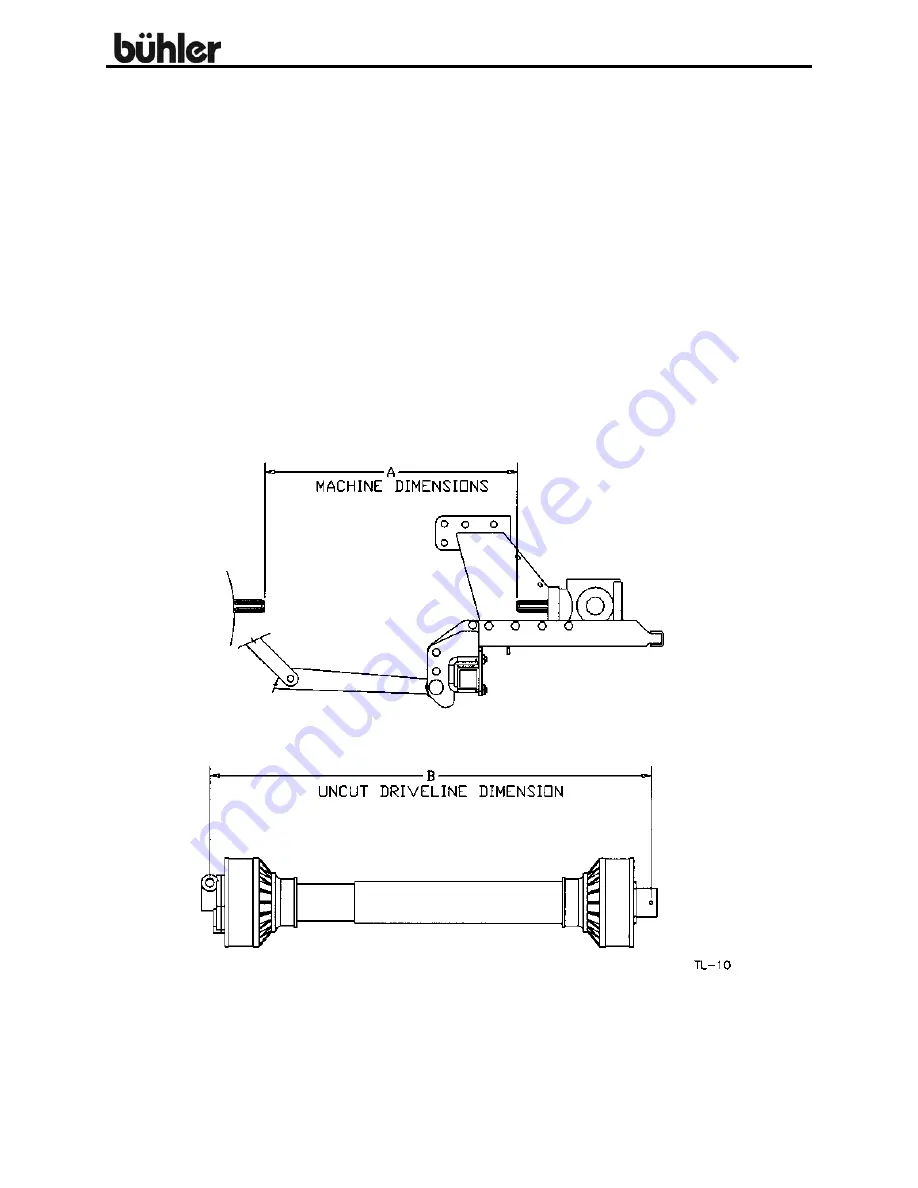

DRIVELINE DIMENSION

A PTO driveline is supplied with the machine. To accommodate the variety of 3 point

hitch geometry available today, the driveline can be too long for some machines and

must be cut. It is very important that the driveline be free to telescope but not bottom

out when going through its working range. If the driveline bottoms out, the bearings on

both the machine and tractor PTO shaft will be overloaded and fail in a short time.

When cutting the driveline, follow this procedure:

1.

Clear the area of bystanders, especially small children.

2.

Attach the Tiller to the tractor but do not attach the driveline.

3.

Raise the machine until the input shaft is level with the tractor PTO shaft.

4.

Measure the dimension between the locking groove on the tractor PTO shaft and

the groove on the Tiller input shaft.

5.

Measure the same dimensions on the compressed driveline.

6.

If the driveline dimension exceeds the machine dimension, the driveline will have

to be cut.

Summary of Contents for 50" Series

Page 1: ......

Page 2: ......

Page 34: ...65 Series Rotary Tiller 30 50 60 72 SERIES TILLERS...

Page 35: ...65 Series Rotary Tiller 31 50 60 72 65 SERIES TILLERS...

Page 36: ...65 Series Rotary Tiller 32 82 65 SERIES TILLER ONLY...

Page 40: ...65 Series Rotary Tiller 36 65 SERIES TILLER PTO SLIP CLUTCH 50 60 72 82...

Page 46: ...NOTES...

Page 47: ......