5

If a valve is set to a higher pressure than the original

set pressure, the rupture of the spring could occur and

a reduction of the distance between the spring coils,

limiting the valves opening, and therefore, the relief

flow would decrease. The “blowdown” would increase.

If set pressure is decreased, would be increased

overpressure in the installation.

Before increasing the set pressure of already installed

valve, be sure to verify that the new pressure is inside

the nominal pressure range it is been designed for.

Also, before decreasing the set pressure, it needs to

be verified that required capacity with new set

pressure is going to be enough to protect the container

it is been for.

4.1 HYDROSTATIC TESTS

When the hydrostatic test of a container is required, it

must be ensured that the safety-relief valve would not

deteriorate.

When making the test upstream, the valve needs to be

nullified, installing the test-gag in order to avoid its

opening.

TEST-GAG

Once the hydrostatic test is finished, the lock

screw needs to be replaced, otherwise the safety-

relief valve would remain completely voided.

When the hydrostatic test is performed upstream, it

has to be checked that the pressure that the valve will

receive does not exceed the limitations of its design,

mainly in those valves including bellows.

4.2 BLOWDOWN ADJUSTMENT

The blowdown pressure regarding the set pressure at

the closing moment of the valve after the popping can

be “adjusted” using the adjusting ring (7) mounted over

the nozzle (4). (Check the drawing in page -8-).

In case the blowdown value should be adjusted, once

the valve is assembled in the installation, proceed as

follows:

- Unscrew the screw (14) which fixes the adjusting ring

(7).

- Using a screwdriver turn the adjusting ring upwards

until making contact with the disc holder (8), then turn

it to the opposite direction so many grooves as Table 1

points out.

- In order to increase the blowdown (the valve will

close itself at a very low inlet pressure) the adjusting

ring has to be risen turning the grooves counter

clockwise (from left to right).

- To decrease the blowdown (the valve will close itself

at a very high inlet pressure) the adjusting ring has to

be lowered turning the grooves clockwise (from right to

left).

- Once the adjusting ring has been adjusted, the lock

screw has to be assembled back, checking that the

stud remains placed inside the adjusting ring‘s groove,

fixing it to keep it from spinning, but free for its

alignment.

5 - MAINTENANCE

If the valve has been working at an installation with

fluids classified as dangerous or pollutant,

decontamination has to be performed prior to its

manipulation.

It is highly important to follow the disassembly

sequence as described below, as any alteration

may be dangerous for the worker who is

manipulating the valve, due to the spring tension.

To achieve a correct valve operation, the use of

original spare parts is essential.

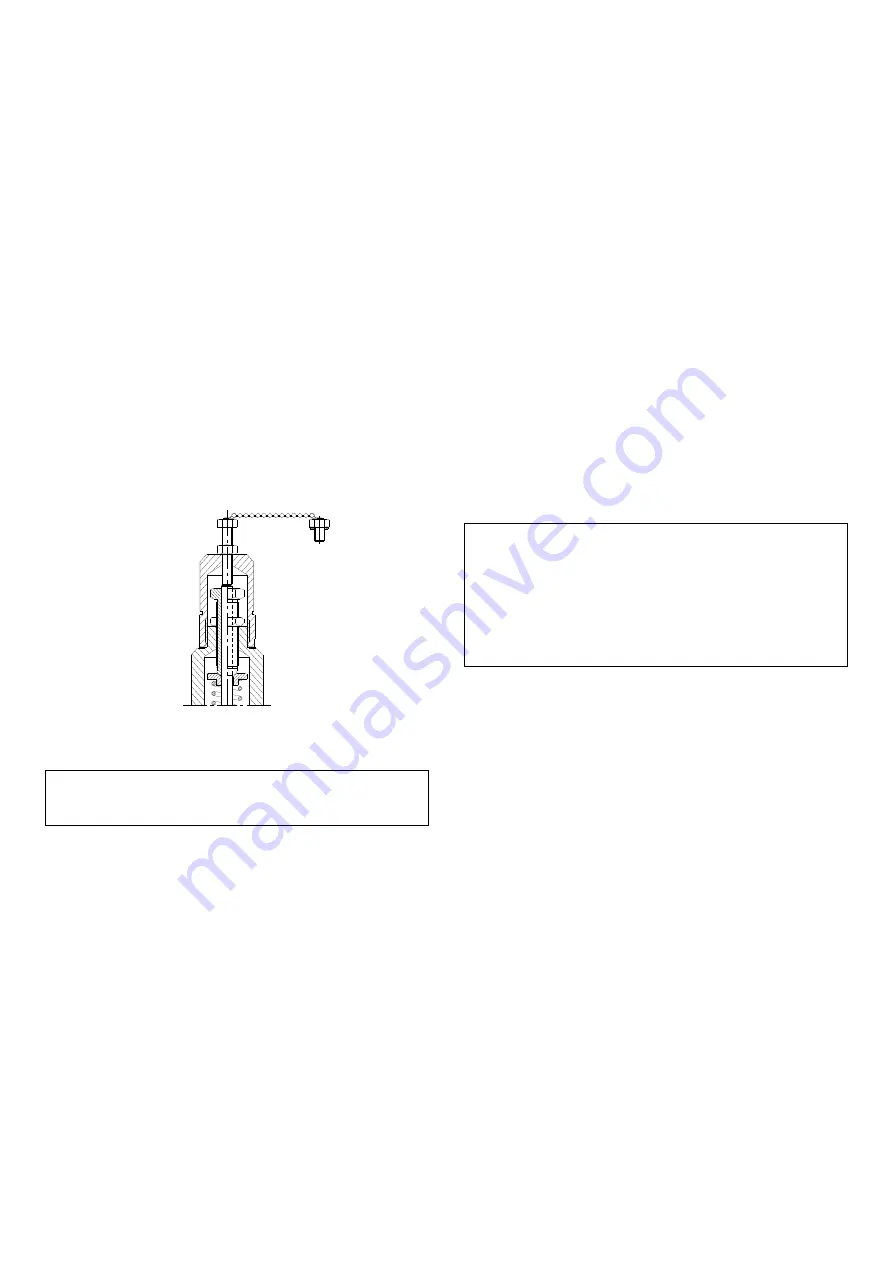

5.1 ASSEMBLY AND DISASSEMBLY - VALVE 3-

5111

To perform the assembly and disassembly operations

check valve section drawings in page -8-.

5.1.1

DISASSEMBLY

Unscrew the cap (3).

If the valve has a lever, disassemble the lever (59),

unscrew the holder (62) and unscrew the cap (53).

Once the position of the release nut (43) is checked by

measuring distance between the top side and the edge

of the stem, loosen the capture (44) and disassemble

it.

Before losing the spring (11), write down the distance

between the top part of it to the edge of the stem. This

will allow to place it in the same position assembled.

Unscrew the adjusting nut (13) and the adjusting screw

(11) until all the tension in the spring is freed (10).