9

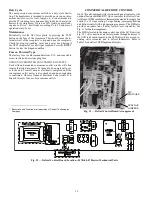

Reinstalling Motor and Fan Assembly

See Fig. 13.

1. Align motor harness/grommet at ~7 o’clock (facing

installer) and align the bottom flats on right and left sides

of fan stator with fan deck ribs. Drop fan assembly down

into fan deck opening and slide back until aluminum stator

is under the rear fan deck brackets.

2. Align (if necessary) two front holes and fasten stator to fan

deck with 2 #10 x

5

/

8

-in. hex head screws (P/N:

AL48AM217). Tighten to 50 in.-lb (5.65 Nm).

3. Reconnect wires for stator temperature limit switch.

4. Pull motor harness tight through grommet and plug it in to

the control box harness and secure in the corner with snap-

in wire tie.

Fig. 13 — Fan Assembly Install

Staged Air Volume

All 547K 07 units with Axion™ Fan technology come factory

set to automatically adjust the indoor fan motor speed in se

-

quence with the unit’s ventilation, cooling, and heating opera

-

tion. When the first stage of cooling is requested, unit fan will

operate at 66% of the user set full load airflow. When the sec

-

ond stage of cooling is required, UCB will allow the full design

airflow rate for the unit (100%). During the heating mode, the

unit will allow total design airflow rate (100%). During venti

-

lation mode, the fan will operate at 66% speed.

See Table 1 on page 5 for 2-Pin DIP switch settings.

COOLING

Condenser Coil (Outdoor)

The condenser coil is fabricated with round tube copper hairpins

and plate fins of various materials and/or coatings (see Model

Number Nomenclature in Appendix A to identify the materials

provided in this unit). The coil may be one-row or composite-

type two-row. Composite two-row coils are two single-row coils

fabricated with a single return bend end tubesheet.

Evaporator Coil (Indoor)

The evaporator coil is traditional round-tube, plate-fin technolo

-

gy. Tube and fin construction is of various optional materials and

coatings (see APPENDIX A — MODEL NUMBER NOMEN

CLATURE on page 54). Coils are multiple-row.

Condenser Coil Maintenance and Cleaning

Recommendation

Routine cleaning of coil surfaces is essential to maintain proper

operation of the unit. Elimination of contamination and remov

-

al of harmful residues will greatly increase the life of the coil

and extend the life of the unit. The following maintenance and

cleaning procedures are recommended as part of the routine

maintenance activities to extend the life of the coil.

REMOVE SURFACE LOADED FIBERS

Surface loaded fibers or dirt should be removed with a vacuum

cleaner. If a vacuum cleaner is not available, a soft non-metal

-

lic bristle brush may be used. In either case, the tool should be

applied in the direction of the fins. Coil surfaces can be easily

damaged (fin edges can be easily bent over and damage to the

coating of a protected coil) if the tool is applied across the fins.

NOTE: Use of a water stream, such as a garden hose, against a

surface loaded coil will drive the fibers and dirt into the coil.

This will make cleaning efforts more difficult. Surface loaded

fibers must be completely removed prior to using low velocity

clean water rinse.

PERIODIC CLEAN WATER RINSE

A periodic clean water rinse is very beneficial for coils that are

applied in coastal or industrial environments. However, it is

very important that the water rinse is made with a very low ve

-

locity water stream to avoid damaging the fin edges. Monthly

cleaning as described below is recommended. Rinsing coils in

the opposite direction of airflow is recommended.

ROUTINE CLEANING OF COIL SURFACES

Periodic cleaning with Totaline

®

environmentally balanced

coil cleaner is essential to extend the life of coils. This cleaner

is available from Replacement Components Division as part

number P902-0301 for a one gallon container, and part number

P902-0305 for a 5 gallon container. It is recommended that all

coils, including standard aluminum, pre-coated, copper/copper

or e-coated coils be cleaned with the Totaline environmentally

balanced coil cleaner as described below. Coil cleaning should

be part of the unit’s regularly scheduled maintenance proce

-

dures to ensure long life of the coil. Failure to clean the coils

may result in reduced durability in the environment.

Avoid use of:

• coil brighteners

• acid cleaning prior to painting

• high pressure washers

• poor quality water for cleaning

Totaline environmentally balanced coil cleaner is nonflamma

-

ble, hypo-allergenic, non-bacterial, and a USDA accepted bio

-

degradable agent that will not harm the coil or surrounding

components such as electrical wiring, painted metal surfaces,

or insulation. Use of non-recommended coil cleaners is strong

-

ly discouraged since coil and unit durability could be affected.

WARNING

UNIT OPERATION AND SAFETY HAZARD

Failure to follow this warning could cause personal injury,

death and/or equipment damage.

This system uses R-410A refrigerant, which has higher

pressures than R-22 and other refrigerants. No other

refrigerant may be used in this system. Gage set, hoses, and

recovery system must be designed to handle R

-

410A

refrigerant. If unsure about equipment, consult the

equipment manufacturer.

1

3

4

2