CAUTION:

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit compo-

nent damage.

Vent pipe must be installed and fully seated against

inducer housing internal stop. Clamp must be tightened to

prevent any condensate leakage.

6. Install casing hole filler cap (factory-supplied in loose parts

bag) in unused vent pipe casing hole.

ATTACHMENT OF VENT EXTENSION PIPE

Furnaces with 100,000 Btuh and larger input are supplied with a

PVC vent extension pipe (2-in. diameter by 12-in. long). This pipe

has a built-in channel to assist vent condensate disposal. When this

vent extension pipe is supplied, it MUST be used to connect the

field vent pipe to furnace inducer housing on ALL upflow and

downflow applications.

NOTE:

See label on vent extension pipe for proper installation.

This pipe may be shortened if an elbow is used to connect vent

extension tube to field-installed vent pipe.

INSTALLATION GUIDELINES FOR COMBUSTION AIR

PIPE AND VENT PIPE

It is recommended that all pipes be cut, prepared, and pre-

assembled before permanently cementing any joint.

1. Attach combustion air pipe and vent pipe per instructions in

sections

″

Combustion Air Pipe

″

and

″

Vent Pipe.

″

2. Working from furnace to outside, cut pipe to required

length(s).

3. Deburr inside and outside of pipe.

4. Chamfer outside edge of pipe for better distribution of

primer and cement.

5. Clean and dry all surfaces to be joined.

6. Check dry fit of pipe and mark insertion depth on pipe.

7. After pipes have been cut and preassembled, apply gener-

ous layer of cement primer to pipe fitting socket and end of

pipe to insertion mark. Quickly apply approved cement to

end of pipe and fitting socket (over primer). Apply cement

in a light, uniform coat on inside of socket to prevent

buildup of excess cement. Apply second coat.

8. While cement is still wet, twist pipe into socket with 1/4

turn. Be sure pipe is fully inserted into fitting socket.

9. Wipe excess cement from joint. A continuous bead of

cement will be visible around perimeter of a properly made

joint.

10. Handle pipe joints carefully until cement sets.

11. Horizontal portions of the venting system shall be supported

to prevent sagging support. Support combustion air piping

(if applicable) and vent piping a minimum of every 5 ft (3

ft for SDR-21 or -26 PVC) using perforated metal hanging

strap.

12. Slope combustion air piping (if applicable) and vent piping

downward towards furnace a minimum of 1/4 in. per linear

ft with no sags between hangers.

13. Horizontal portions of the venting system shall be installed

so as to prevent the accumulation of condensate.

14. Use appropriate methods to seal openings where combus-

tion air pipe (if applicable) and vent pipe pass through roof

or sidewall.

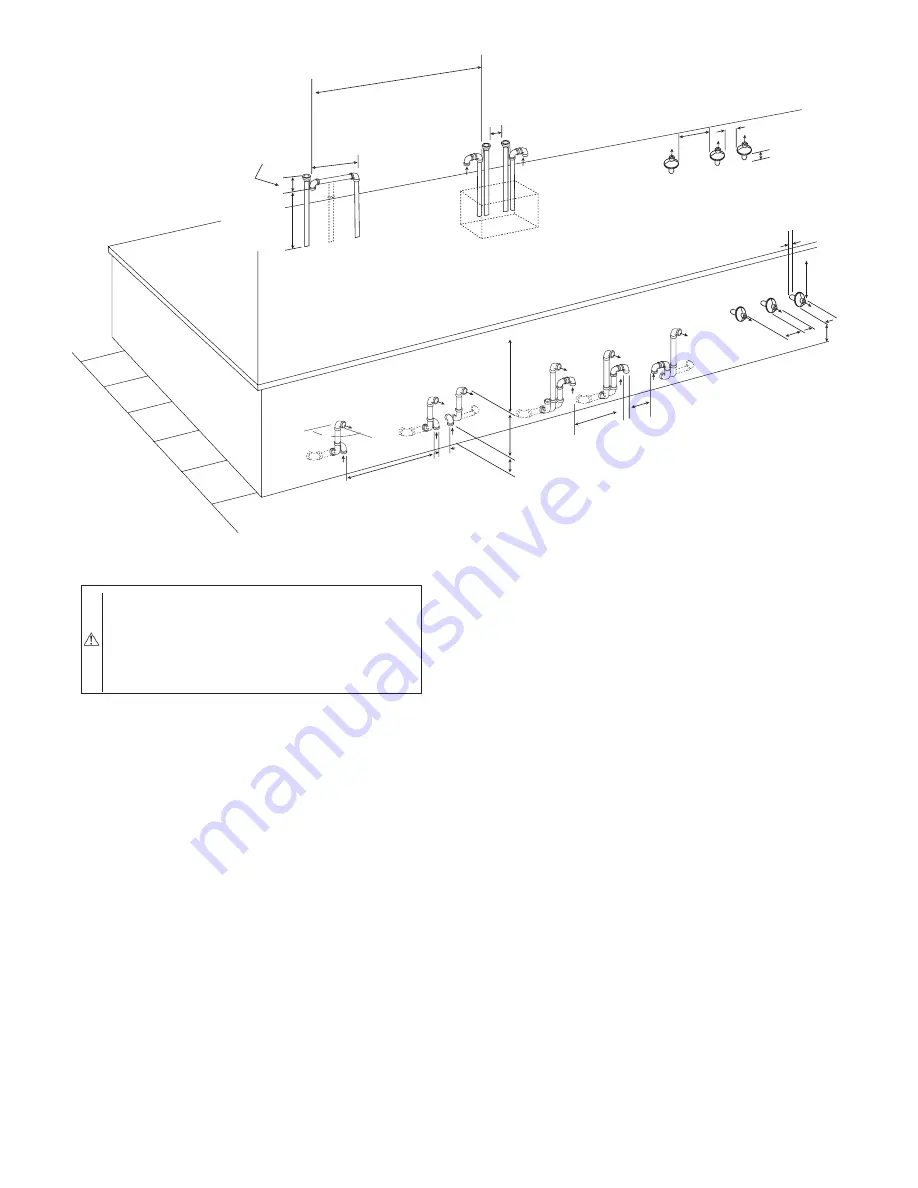

Fig. 42—Combustion Air and Vent Pipe Termination

for Direct Vent (2-pipe) System (All Sizes)

A05090

At least 36 in.

18 in. maximum

Vertical separation

between combustion

air and vent

8 3/4 in. for 3 in. kit

6 3/4 in. for 2 in. kit

Roof Termination (Preferred)

Abandoned masonry

used as raceway

(per code)

At least

36 in.

A

Maintain 12

in.

min. clearance above

highest anticipated

snow level, maximum of

24 in. above roof

Concentric Vent and Combustion Air

Roof Termination (preferred)

1

in.

maximum (type)

12

in.

minimum from

overhang or roof

Maintain 12

in.

min. clearance above

highest anticipated

snow level or grade

whichever is greater

A

At lea

st

36

in.

Concentric Vent

and Combustion - Air

Side Termination

A

At least 36 in.

Side wall termination

of less than 12

in.

12

in.

min from

overhang or roof

12

in.

separation

between bottom of

combustion air and

bottom of vent

Maintain 12

in.

min. clearance above

highest anticipated

snow level or grade

whichever is greater

A

At least 36 in

.

A

Maintain 12 in. min.

clearance above

highest anticipated

snow level

Maximum of 24 in.

above roof

90

°

Note: "A" denotes 0 to < 2 in.

—39—

→