DO NOT INSTALL A BAROMETRIC DRAFT

CONTROL IN A ROOM SEPARATE FROM THE

BOILER.

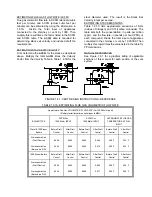

The stop and two cover plates are painted in a different

color for easy identification. To remove the stop simply

remove the two screws that hold it to the ring. See Fig.

1.8.6B. To remove cover plates (Item B), bend or break

off the tab that goes through the small hole in the ring.

DO NOT REMOVE THE STOP ATTACHED TO THE

GATE (Item C).

INSTALLATION

Insert the draft control into the collar. The front face of

the control MUST BE PLUMB. The bearing surfaces

MUST BE LEVEL whether the control is on a

horizontal, vertical, or sloping flue pipe. Using a spirit

level, plumb and level accurately. Secure the control in

the collar by tightening the clamping screws. If the

collar is supplied locally, the control may be held in

place by small bolts or sheet metal screws. If the

control has any tendency to sag support it from

overhead.

NOTE: Spill switch provided by others. See wiring

diagram for control point connection.

VERTICAL FLUES

The control is shipped for installation in a vertical flue.

The screw should be left in the top hole of the weight

lever. (Item D)

HORIZONTAL FLUES

For horizontal flues, remove the screw from the upper

hole in the weight lever and insert it in the lower hole.

(Item E)

ADJUSTING THE CONTROL

The control is adjusted to achieve the desired DRAFT

or CO

2

by adding or removing weights (washer type,

Item F) at the end of the chains. DO NOT MOVE THE

LARGE WEIGHTS ATTACHED DIRECTLY TO THE

GATE (Item G) as they are used only for adjustment at

the factory.

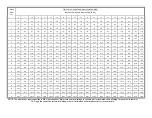

DRAFT should generally be set between -0.02" and -

0.04" w.c. The actual setting must be determined by

taking a CO

2

reading and a CO reading at the boiler

flue. Reference Table 2.5A for appropriate values.

COMBUSTION READINGS AND DRAFT SETTINGS

MUST BE DONE BY A QUALIFIED BOILER SERVICE

TECHNICIAN.

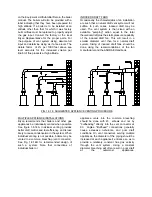

HIGH DRAFT CONDITIONS

On some installations, because of a high stack, the

draft may be too great to be adjusted using only the

barometric regulator weights. When this occurs, install

a sheet metal baffle through the barometric draft

regulator opening as described in Figure 1.8.6C. The

baffle installation is correct if the gate of the barometric

control is approximately half open while the burner is

operating, and CO

2

, CO and draft readings are correct.

Barometric

Size (diameter)

Sheet Cut / Form Dimensions

10"

12"

14"

16"

18"

20"

24"

28"

30"

10"

12"

14"

16"

18"

20"

24"

28"

30"

14"

16 3/4"

19 1/2"

22 1/2"

25"

28"

33 1/2"

37"

44"

5"

6"

7"

8"

9"

10"

12"

14"

16"

NOTE THAT THE GATE MUST SWING FREELY

AFTER THE BAFFLE IS INSTALLED.

DO NOT RESTRICT THE BREECHING BETWEEN

THE BAROMETRIC DRAFT CONTROL AND THE

CHIMNEY OR VENT.

CAUTION SHOULD BE USED TO INSURE AGAINST

OVER-RESTRICTING THE FLUE. ALWAYS BE

CERTAIN THAT COMBUSTION IS CORRECT AND A

DRAFT EXISTS AFTER THE BAFFLE IS INSERTED

AND SECURED IN PLACE.

NOTE that the dimension for baffles may vary due to

different types of flue connections and tee sizes.

Summary of Contents for AB Series

Page 22: ......