Bandit

40

Copyright 6/12

MODEL 200 UC

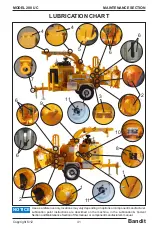

A right angle grease fitting may need to be used to grease some of the lubrication

points. This type of grease fitting can be obtained from most local automotive

parts stores.

Use as a reference only, locations may vary depending on options or component manufacturer.

Lubrication point instructions are described on the machine, in the Lubrication & Coolant

Section and Maintenance Section of this manual, or component manufacturer’s manual.

NOTICE

MAINTENANCE SECTION

LUBRICATION CHART

CHECK

# DESCRIPTION

DAY WEEK MONTH PROCEDURE

1 Disc/Drum Bearings

X

Purge bearings daily ‑ wipe off excess

2 Feedwheel Bearings

X

1 shot of grease ‑ wipe off excess

3 Hood Hinge

X

1 to 2 shots of grease ‑ wipe off excess

4 Steel Friction Areas: pivoting,

X

Lubricate (i.e. control handle, discharge

hinged, sliding, rolling

flipper, folding pan, etc)

5 Chain Driven Components

X

Dry lube (Swivel discharge, chain driven

feedwheels, etc)

6 Feedwheel Slide Box

X

Clean and oil with 10W/30

7 Pintle Eye Ring

X

Grease to reduce wear

8 Bandit Throttle Cable

X

Lubricate inner cable & ends SAE 10W/30

9 Discharge Swivel Plates

3 Months Grease as needed

10 Clutch

Grease per MFG’s instructions

11 Wheel Bearings

Grease or oil per MFG’s instructions

4

4

4

Summary of Contents for 200 UC

Page 17: ......

Page 35: ...Bandit 19 Copyright 6 12 MODEL 200 UC DECALS ...

Page 36: ...Bandit 20 Copyright 6 12 MODEL 200 UC DECALS ...

Page 69: ...Bandit 53 Copyright 6 12 MODEL 200 UC HYDRAULIC SECTION HYDRAULIC SECTION ...

Page 126: ...Bandit 110 Copyright 6 12 MODEL 200 UC SERVICE RECORD SERVICE RECORD DATE DESCRIPTION AMOUNT ...