Summary of Contents for SmartCooler BCU I

Page 1: ...SmartCooler BCU I User Manual Version 003 Innovation with Integrity NMR...

Page 12: ...Safety 12 Z33119_2_003...

Page 18: ...Introduction 18 Z33119_2_003...

Page 28: ...Preparation 28 Z33119_2_003...

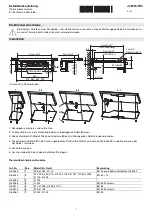

Page 30: ...Installation 30 Z33119_2_003...

Page 42: ...Troubleshooting 42 Z33119_1_003...

Page 44: ...Replacement of Parts 44 Z33119_2_003...

Page 48: ...Contact 48 Z33119_2_003...

Page 49: ...Z33119_2_003 49...

Page 50: ...Bruker Corporation info bruker com www bruker com Order No Z33119...