23

Maintenance

Tightening Carbide Tip Bolts

Inspect carbide tip screws each hour for the first eight hours of use for proper torque.

Repeat hourly

inspections each time the carbide tips are removed/replaced.

1. Disengage hydraulics; be certain that all rotation has stopped.

2. Lift Tree Saw high enough to place suitable supports under the Tree Saw deck.

3. Turn Skid steer engine off; remove key; lock transmission and brakes; chock wheels or tracks.

4. Disconnect hydraulic lines.

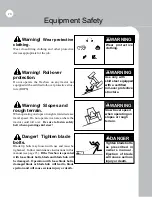

Warning!

Failure to keep blade bolts tight can and will cause: blade breakage; warping of blade;

and/or ejection of blade from TreeSaw. These hazards can cause serious injury or death.

Warning!

If blade tip bolts are allowed to run loose, the obvious danger is for the bolts to come

out, allowing the blade tips to be ejected from the Tree Saw.

The described occurrences will cause the blade to break and be ejected. An ejected blade

can and will cause serious injury or death.

Proper Bearing Block Lubrication

Connect grease gun, with proper lubricant (

Mobiltemp SHC 32 Grease),

onto grease fitting on bearing

block. Pump grease into unit until grease comes out of pressure vent in the opposite side of the bear-

ing block.

Do not overgrease.

Make certain both fittings are tightened securely before operating.

Ordering replacement parts

Please contact the nearest Brown dealer for replacement parts. Or call Brown Mfg. at 800-633-8909

for parts or technical information. Please have model and serial number available when ordering parts.