5-06

5. ADJUSTMENTS

LZ2-B850,B851

r

u

w

t

q

e

w

A

1

2

A

1

2

C

1

2

C

1

2

For zigzag width 8mm

B850W, B851

1051S

1050S

For zigzag width 5mm

B850-1

0601M

0602M

y

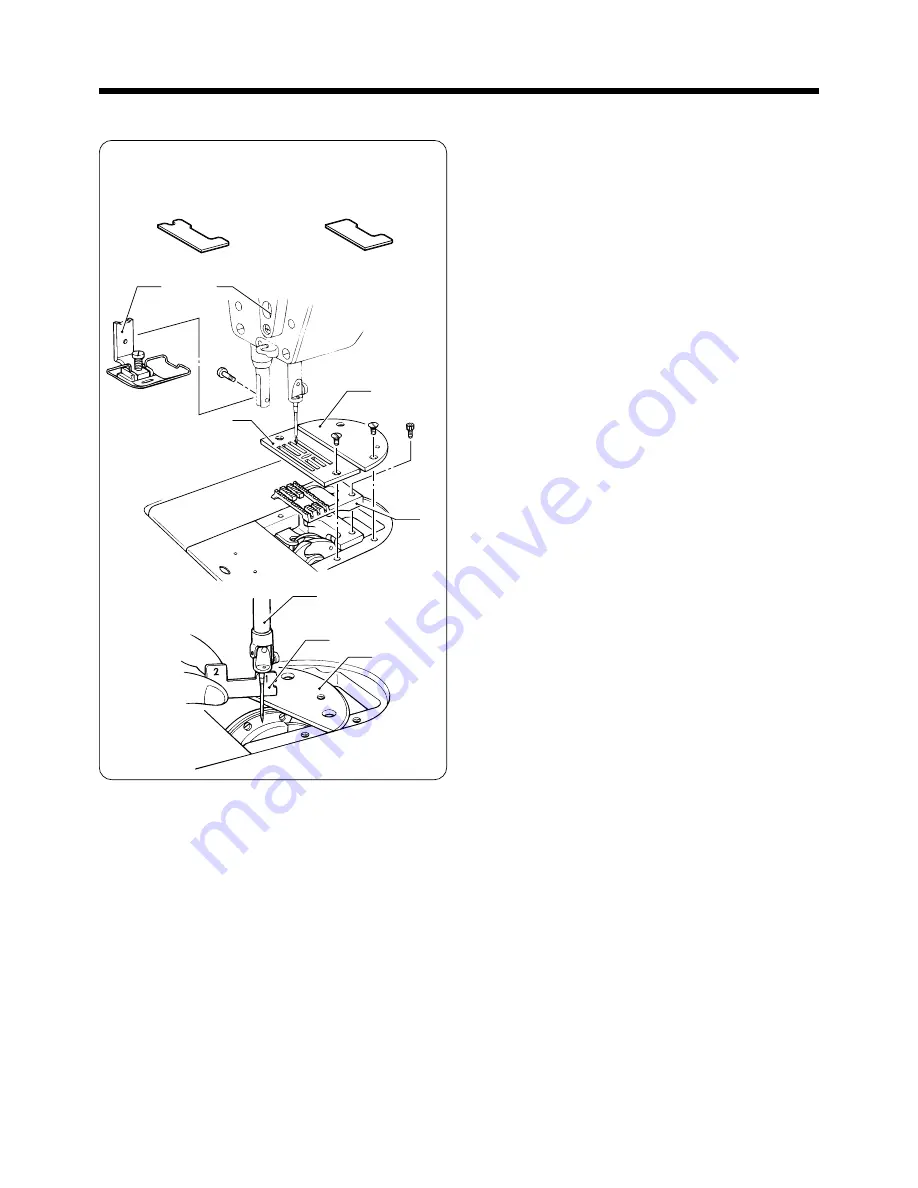

5-8. Adjusting the needle bar height

When the needle bar

q

is at its lowest position, the dis-

tance from the top of the auxiliary needle plate

w

to the

bottom edge of the needle bar

q

should be the same as

the height of accessory timing gauge 1

e

.

1. Remove the presser foot

r

, needle plate

t

, auxiliary

needle plate

w

and feed dog

y

.

2. Place the auxiliary needle plate

w

on the needle plate

installation surface of the machine bed.

3. Turn the machine pulley to move the needle bar

q

to

its lowest position.

4. Loosen the screw

u

.

5. Move the needle bar

q

up or down to adjust the dis-

tance from the top of the auxiliary needle plate

w

to

the bottom edge of the needle bar

q

so that it is the

same as the height of accessory timing gauge 1

e

.

Note:

The needle plate

t

and the auxiliary needle plate

w

are of different thicknesses, so be sure to use the aux-

iliary needle plate

w

.

6. Securely tighten the screw

u

.

7. Install the presser foot

r

, needle plate

t

, auxiliary

needle plate

w

and feed dog

y

.

*

When adjusting the needle bar height, be sure to ad-

just “5-15. Adjusting the needle and rotary hook tim-

ing” also. (Refer to page 5-12.)

*

When remove the feed dog. be sure to adjust “5-5.

Adjusting the forward/back, right/left position of the

feed dog”. (Refer to page 5-03.)