5-28

Confidential

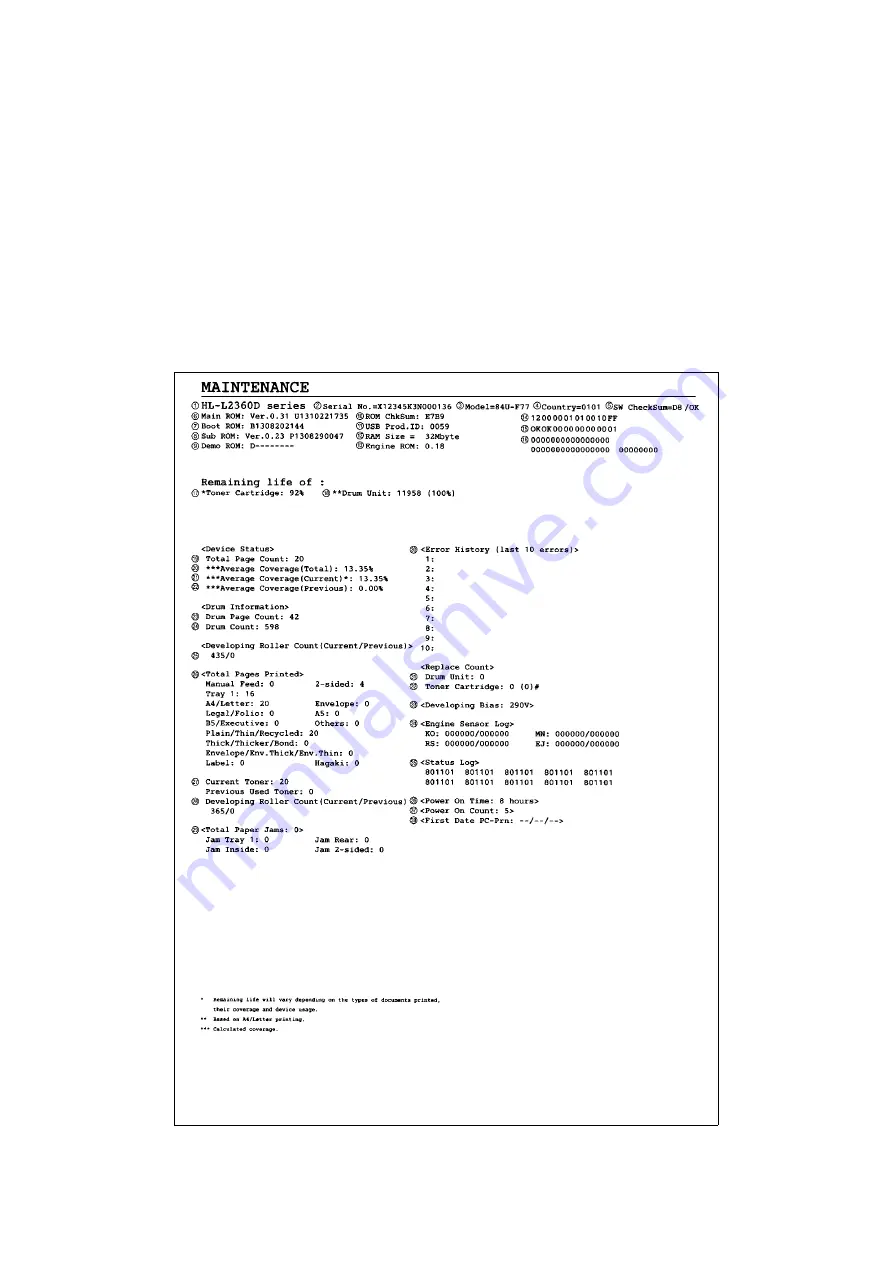

1.3.16 Print maintenance information (function code: 77)

<Function>

This function is used to print the maintenance information, such as remaining amount of

consumables, the number of replacements, and counter information.

<Operating Procedure>

(1) Press the [▲] or [▼] key in the initial state of maintenance mode to display

"MAINTENANCE 77" on the LCD, and press the [OK] key. Printing maintenance

information starts.

When printing is completed, the machine returns to the initial state of maintenance

mode.

Maintenance information

Fig. 5-10