9. STANDARD ADJUSTMENTS

DA-927A, DA-928A

17

9. STANDARD ADJUSTMENTS

CAUTION

Maintenance and inspection of the sewing machine should only be carried out by qualified personnel.

Ask your Brother dealer or a qualified electrician to carry out any maintenance and inspection of the electrical system.

Turn off the power switch and disconnect the power cord from the wall outlet at the following times.

However, the motor will keep turning even after the power is switched off as a result of the motor’s inertia. Wait until the

motor stops fully before starting work.

The machine may operate if the treadle is depressed by mistake, which may result in injury.

When carrying out inspection, adjustment and maintenance

When replacing consumable parts such as the looper

If any safety devices have been removed, be absolutely sure to re-install them to their original positions and check that

they operate correctly before using the machine.

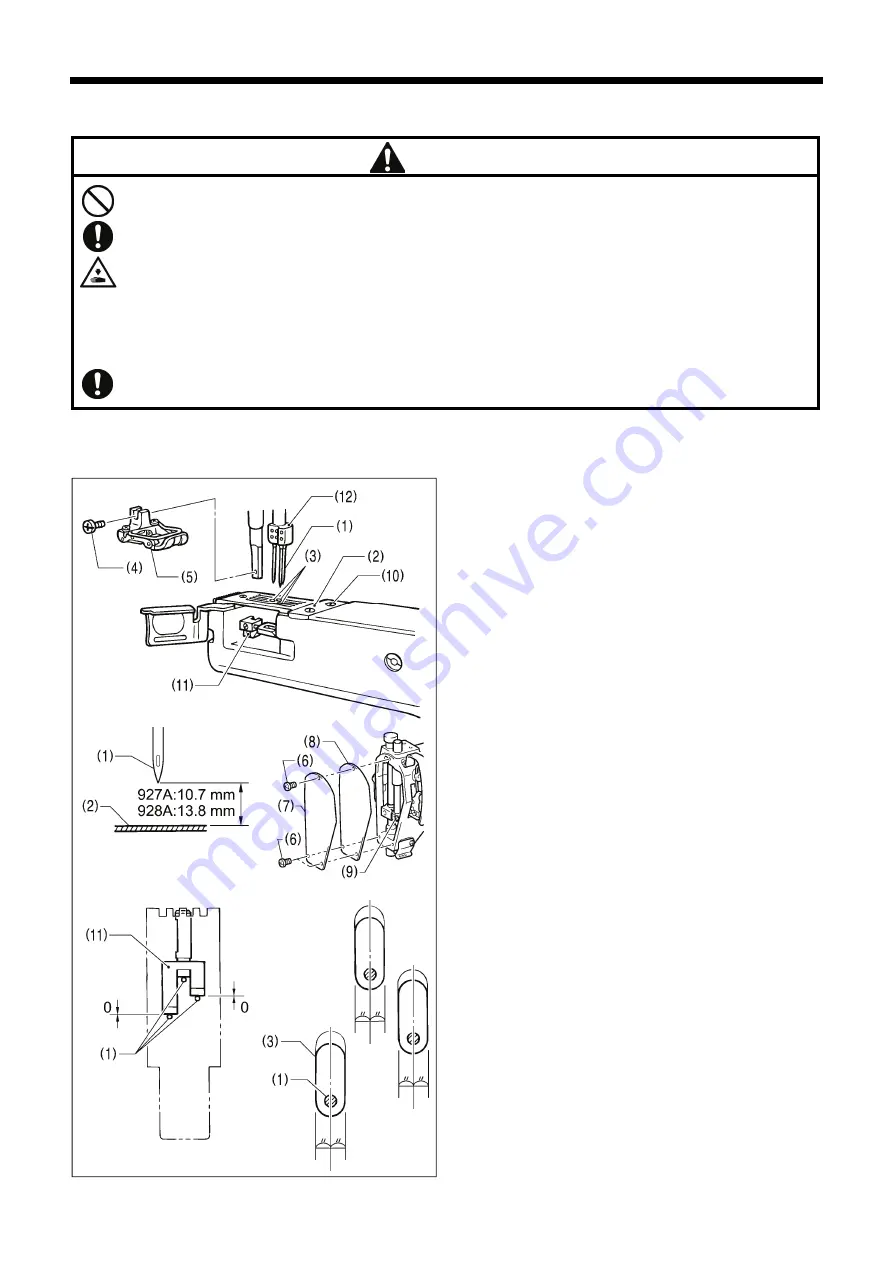

9-1. Needle bar height adjustment

Adjust the heights of the needles (1).

At this time, adjust so that each needle (1) is in the center of the

needle hole (3) in the needle plate (2).

1. Remove the screw (4), and then remove the presser foot (5).

2. Turn the machine pulley to raise the needle bar to its highest

position.

3. Remove the three screws (6), and then remove the face

plate (7) and the face plate packing (8) and loosen the screw

(9) of the needle bar clamp.

4. Move the needle clamp (12) up or down to adjust so that the

distance from the needle tip to the top of the needle plate (2)

is as shown in the illustration when the needle (1) is at its

highest position.

5. Rotate the needle clamp (12) so that the needle (1) is in the

center of the needle hole (3) of the needle plate (2) when the

machine pulley is turned so that the needle (1) goes into the

needle hole (3).

6. Tighten the screw (9), and then install the face plate (7) and

the face plate packing (8) with the three screws (6).

7. Install the presser foot (5) with the screw (4).

*

Turn the machine pulley and check that the

clearances between the left and right sides of the

needle (1) and the needle guard (11) are uniform

when the needle (1) and the needle guard (11) are

aligned.

1512B

4270B

4271B

4272B

4269B