79

4

d

Ignore Object Size Key

Small unnecessary patterns (dotted lines, etc.)

can be excluded from cutting data. For details,

see “Specifying “Ignore Object Size”” on

page 81.

e

Smoothing Setting Key

Specify the level of smoothing applied to the

image outline. For details, see “Specifying

Smoothing” on page 82.

f

OK Key

Touch the “OK” key to apply the settings. When

the number of colors is changed, the “OK” key

changes to the “Preview” key. After changing

the number of colors, touch the “Preview” key

to check the results.

Memo

•

When making a stamp, for example, the image

may not be converted to cutting data if it

contains a gradation or areas that are only

partially filled with a color.

■

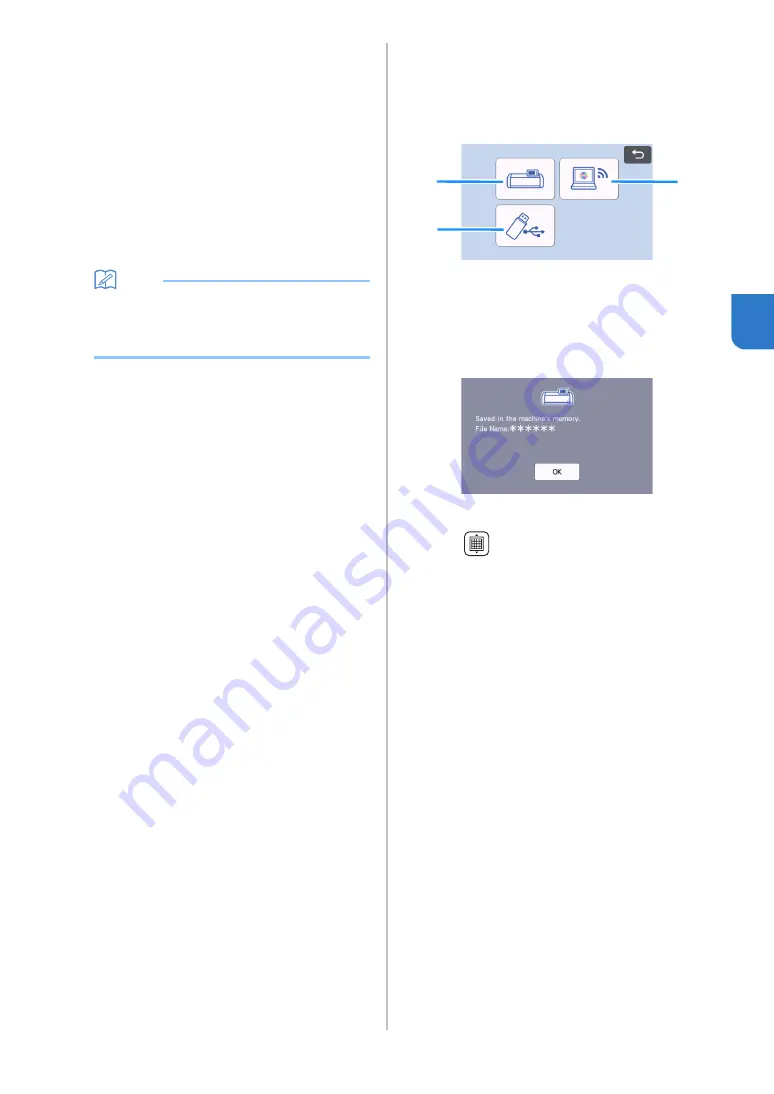

Saving Data

a

Select the destination where the data will be

saved.

Select the desired location. For this example, select the

machine.

a

Save to the machine's memory.

b

Save to the USB flash drive.

c

Transfer to CanvasWorkspace.

Touching a key starts saving the data. When the

data has been saved, the following message

appears.

b

Touch the “OK” key to finish saving the data.

c

Press

in the operation panel to feed out

the mat, and then peel off the original from the

mat.

c

b

a