5

123

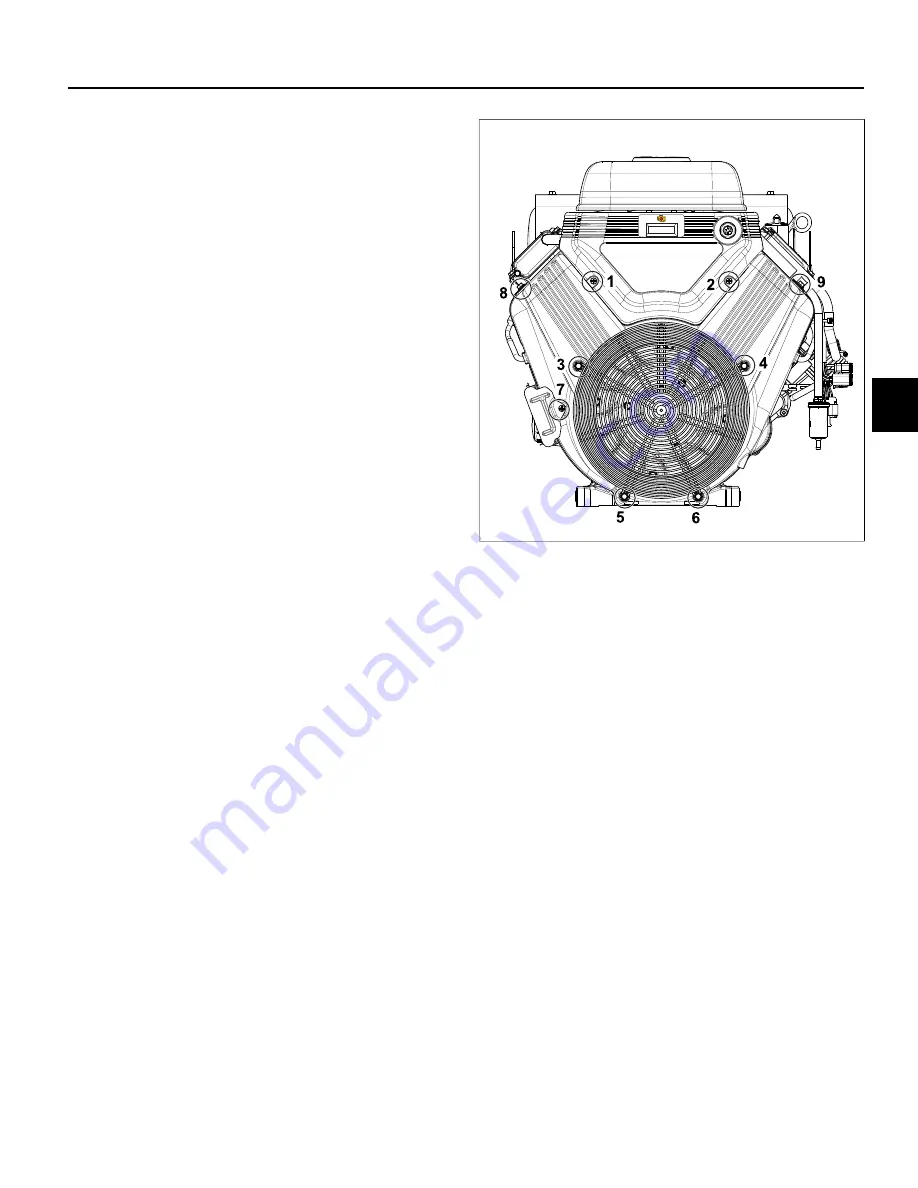

MODELS 540000/610000 FUEL SYSTEM COMPONENTS

Access Cover/Blower Housing

Removal

1. See Figure 21. Remove two Phillips screws (

1-2

) to

release access cover from blower housing.

2. Lift access cover straight up to release tongues from

grooves in blower housing.

3. If equipped, disconnect tachometer/hourmeter/MIL

connector at back of access cover.

4. Remove four hex flange screws (

3-6

) from coupling

nuts to release wire guard.

5. Remove hex flange screw (

7

) to release oil cooler

bracket from blower housing.

6. Remove hex flange screws (

8-9

) to release left and

right side air guides and blower housing from intake

manifold.

7. Remove four coupling nuts (

3-6

). Lift blower housing

straight up to disengage from posts.

Installation

1. Place blower housing into position engaging holes

with four posts.

2. Verify high tension leads are routed through slots on

each side or damage will occur when blower housing

is tightened.

3. Install coupling nuts on posts (

3-6

). Alternately

tighten coupling nuts to

78-96 lb-in

(9-11 Nm) using a

crosswise pattern.

4. Install two hex flange screws (

8-9

) to fasten left and

right side air guides and blower housing to intake

manifold. Tighten screws to

78-96 lb-in

(9-11 Nm).

5. Install hex flange screw (

7

) to fasten oil cooler bracket

to blower housing. Tighten screw to

35-43 lb-in

(4-5

Nm).

6. Install four hex flange screws (

3-6

) to fasten wire

guard to coupling nuts. Tighten screws to

78-96 lb-in

(9-11 Nm).

7. If equipped, connect tachometer/hourmeter/ MIL

connector at back of access cover.

8. Lower access cover straight down to engage tongues

in grooves of blower housing.

9. Verify IAC connector wire harness conduit is routed

through groove or damage will occur when access

cover is tightened.

10. Install two Phillips screws (

1-2

) to fasten access

cover to blower housing. Tighten screws to

35-43 lb-

in

(4-5 Nm).

21

ECM

NOTE:

A product improvement to dampen vibration to

the ECM/fuse block bracket was recently introduced in

production. A Briggs & Stratton Service Kit (Part No.

847337) to upgrade product in the field includes a new

fuse/relay block cover, ECM mounting bracket, rubber

isolation mounts, and mounting hardware. See Service

Bulletin DSB-1053 for details.

Removal

1. Remove access cover. See

Access Cover/Blower

Housing, Removal,

steps 1-3.

2. Remove two Phillips screws to release ECM from

ECM/fuse block bracket.

3. Disconnect J1 and J2 connectors from ECM.

Installation

1. Connect J1 and J2 connectors to

new

ECM.

NOTE:

The words BLACK and GREY are molded into

the ECM housing to ensure proper installation of J1

(Grey) and J2 (Black) connectors.

2. Slide Phillips screw through ECM flange (Grey ECM

J1 connector side) and ground wire ring terminal.

Start screw into ECM/ fuse block bracket.

Not for

Reproduction

Summary of Contents for VANGUARD M490000

Page 2: ...N o t f o r R e p r o d u c t i o n ...

Page 6: ...N o t f o r R e p r o d u c t i o n ...

Page 84: ...3 80 MODEL 490000 EFI ELECTRICAL SCHEMATIC PAGE 1 OF 2 N o t f o r R e p r o d u c t i o n ...

Page 85: ...3 81 MODEL 490000 EFI ELECTRICAL SCHEMATIC PAGE 2 OF 2 N o t f o r R e p r o d u c t i o n ...

Page 95: ...3 91 MODELS 490000 540000 610000 FUSE RELAY BLOCK N o t f o r R e p r o d u c t i o n ...

Page 96: ...3 92 N o t f o r R e p r o d u c t i o n ...

Page 110: ...4 106 N o t f o r R e p r o d u c t i o n ...

Page 115: ...5 111 This page is intentionally left blank N o t f o r R e p r o d u c t i o n ...

Page 134: ...5 130 30 N o t f o r R e p r o d u c t i o n ...

Page 137: ...5 133 This page is intentionally left blank N o t f o r R e p r o d u c t i o n ...

Page 138: ...5 134 32 N o t f o r R e p r o d u c t i o n ...

Page 140: ...5 136 33 N o t f o r R e p r o d u c t i o n ...

Page 142: ...5 138 This page is intentionally left blank N o t f o r R e p r o d u c t i o n ...