5

MAINTENANCE

Draining carburetor

The carburetor should be “purged”

of alcohol at the end of every day of

running. Alcohol is very corrosive and

will cause a lot of problems if left in the

carb. The fuel line should be unhooked

at the carburetor and the bowl drain

screw opened to drain any fuel in the

system. Another option is to run the

engine on gasoline until it stalls. This

will flush any alcohol out of the system.

The carburetor should also be drained

at least at the end of the season when

running gasoline.

Filters

Always use an inline fuel filter to

prevent contamination inside the

carburetor. Air filters should fit the

carburetor properly and be kept clean.

Bowl gasket

When reinstalling the float bowl you

may find the gasket does not fit

properly. If the gasket is too small it

can be stretched to fit the groove. If

it is wet it may swell slightly and can

be set aside to dry and return to the

proper size. If you are doing a lot of

disassembly for tuning it may help to

have extra gaskets.

Cleaning/Inspection

Once a year the carburetor should

be disassembled for cleaning and

inspection. Look for wear on the jet

needle and inlet tip. Inspect and/or

replace o-rings and seals. If cleaning

is necessary a toothpick will work

for clearing any holes such as jets.

Remove the Inlet Needle and use a

Q-tip to clean the inside of the inlet

seat. Compressed air is also useful to

remove contamination. The pilot jet

has a very small metering orifice. If it

cannot be blown out it will likely need

to be replaced.

Always use a stop on the gas pedal.

This reduces wear on the carburetor

and the chance of a stuck throttle.

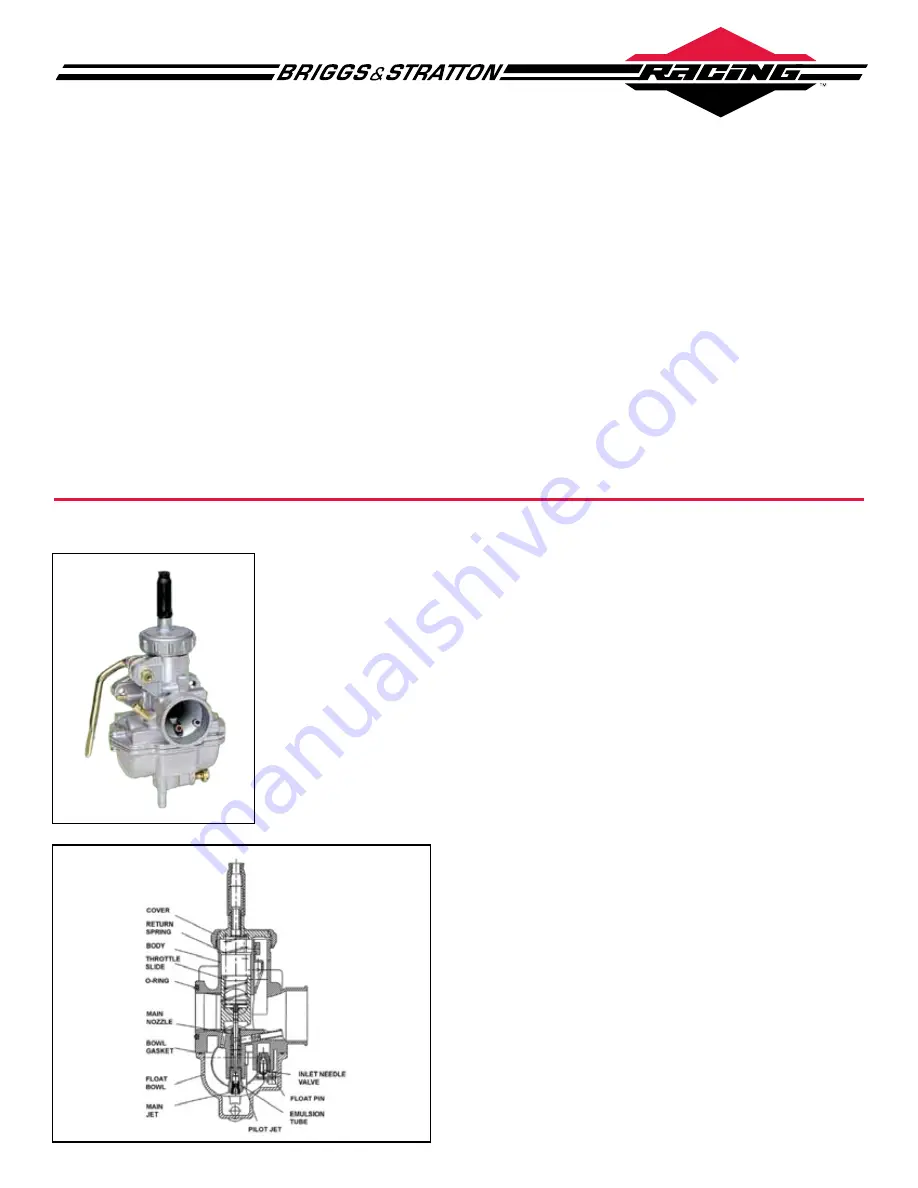

SPECIFICATIONS & EXPLODED VIEWS

Animal, 206, and

M-series

Main Jet: 95

Pilot Jet: 32

Main Nozzle Diameter: 2.6

Jet Needle: BGB/2nd notch

Mixture Screw: 1 ½ turn

Float Height: 22.0mm (.860in)