Operation and Safety Manual

™

Model GPR Belt Driven Gravity Slicers

6

The Brice Model GPR slicers have been designed for environments where a range of different

foodstuffs and slicing requirements must be met – from individual slices to larger batches.

The Model GPR, one of the most versatile on the market is designed for precision slicing.

Available in three blade sizes (220mm, 250mm & 300mm).

•

Manufactured in anodised aluminium and stainless steel to resist oxidisation and corrosion;

•

Constructed for easy cleaning;

•

Thickness control knob allows for cutting of slices from 0 to 15mm;

•

Last Slice device to minimise waste in slicing processed foodstuff stubs;

•

Self-contained and built-in sharpening device with grinding and finishing stones;

•

Forced ventilation to motor to prevent overheating;

•

Low voltage switching;

•

Blade ring guard;

Components of the model range

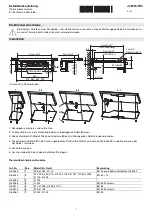

The following picture illustrates the main components of the slicer.

The Brice Model

GPR Slicers

1 Thickness control

2 Meat carriage

3 Blade

4 Blade guard

5 Blade cover

6 Sharpener cover

7 ON/OFF switch

8 Last slice device

9 Meat carriage handle

10 Thickness plate

11 Slice receiving tray

12 Carriage securing knob

13 Blade cover securing knob

14 Slice deflector

1

12

2

8

9

3

5

4

11

6

7

GPR all

machines

GPR300

10

13

14