Document # 101522 0608 REV A ER 784

4

WarnInG

When performing a cauterization or similar treat-

ment, the patient must be insulated from the metal

portions of the table by nonconductive material.

failure to do so may result in electrical shock or

burns to the patient.

WarnInG

Use 115 VaC, 60 Hz alternating current only. failure

to do so may result in electrical shock to personnel

and will result in damage to the table.

WarnInG

Do not use this table in an explosive or oxygen-

enriched atmosphere. failure to do so may result

in serious personnel injury or death.

CaUtIOn

Do not use any power supply other than that

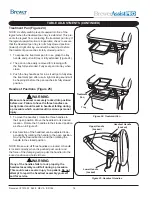

listed on the rating label (figure 1). failure to do

so may result in serious injury and/or equipment

damage.

SpECIfICatIOnS

Power Cord.......................................................................

............ Extends 70 in. (Minimum) from table. 18 AWG / 3

............. conductor, SJT grey jacketed junior hard service

............with hospital plug

Type of protection against electrical shock …….. Class 1

.......................................................................... Grounded

Type of protection

against electrical shock …….. .................. B applied parts

Type of protection against ingress of water……. Ordinary

Type of protection against ingress of water for foot control..IPX1

Can accept paper rolls of

....................................................................18 in. x 3.0 in.

....................................................................21 in. x 3.0 in.

Certifications

*

.................................UL6060-1; UL2601-1;

..........................IEC60601-1; CAN-CSA C22.2 No. 601.1

Transport and Storage Conditions:

Temperature Range......................................-20º to 150º F

Relative Humidity...........................................10% to 90%

Operating Conditions:

Temperature Range ........................................ 65° to 85°F

Relative Humidity...........................................10% to 90%

*

ETL classified in the United States and Canada

per the following standards.

Weight of Table .....................................................550 lbs.

Load Rating (maximum):

Seat/Back .............................................................450 lbs.

Legrest (Flat & Kneeling) ......................................450 lbs.

Headrest ...............................................................100 lbs.

Back Section Range ...............0° (horizontal) to +85° ± 5°

Table Top Height Range ...........19 ± 0.5 in. to 40 ± 1.0 in.

Leg Section Range ............0° (horizontal) to 90° (vertical)

Table Top

Tilt Range ................ 0° (horizontal) to +30° ± 5° (foot up)

Dimensions:

Upholstered Headrest..................13 in. wide x 11 in. high

Upholstered Top ....................28.0 in. wide x 44.5 in. long

Upholstered

Leg Rest ....…………………16.5 in. wide x 11.25 in. high

Overall Length ..................................................69 in. long

With Headrest/

Footrest Extended ............................................90 in. long

Electrical Requirements

..................115 VAC nominal, 60 HZ, 5.8 amps maximum

Duty Cycle (10%)

................. 2 minutes on / 18 minutes off (motor run time)

ELECtrICaL rEqUIrEMEntS

CaUtIOn

this product has been evaluated with respect to

electrical shock, fire, and mechanical hazards only

in accordance with UL60601-1; IEC60601-1;

UL2601-1; Can/CSa C22.2 no. 601.1