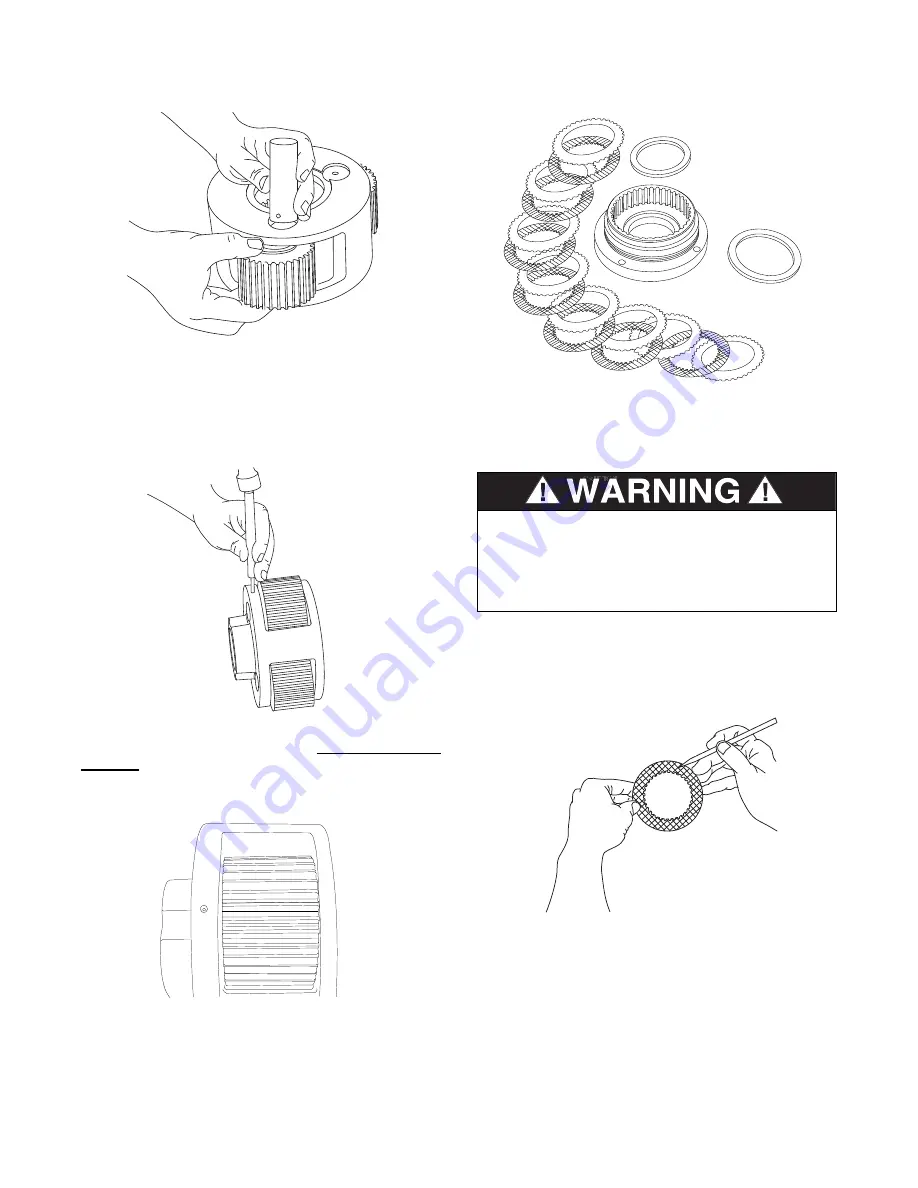

STATIC BRAKE SERVICE

1. Remove all friction and steel discs (items 27 & 28)

and both spacer plates (item 24) from the motor adapter.

1. Thoroughly clean and inspect all parts at this time.

Check brake piston sealing surfaces on motor adapter

and brake cylinder (item 2) for damage or excessive

wear. Be sure the brake release port in the brake cylin-

der is open and free of contamination.

2. Place each friction disc on a flat surface and check

for distortion with a straight edge. Friction material should

appear even across entire surface with groove pattern

visible. Replace friction disc if splines are worn to a point,

disc is distorted, friction material is worn unevenly, groove

pattern is worn away or friction material is burned. Place

each steel disc on a flat surface and check for distor-

tion with a straight edge. Check surface for signs of mate-

rial transfer or heat. Replace steel disc if splines are

worn to a point, disc is distorted or heat discolored.

16

Assembly

1. Insert two bearings with a spacer between them into

a planet gear. Place a thrust race on each side of the

gear and position this assembly in the planet carrier.

Slide the planet gear shaft through the carrier and gear

assembly, aligning the pin hole in the shaft with the hole

in the carrier.

2. Drive a NEW rollpin into place.

Always use NEW

rollpins.

When properly positioned, 50% of the rollpin

length should be engaged in the planet gear shaft with

the remaining 50% in the carrier.

3. With a center punch, stake the carrier next to the pin

hole. This will distort the hole in the carrier so the rollpin

will not back out when in service. Repeat steps 1 through

3 for each of the other two gears.

DO NOT CLEAN BRAKE FRICTION DISCS

IN SOLVENT. SOLVENT MAY CAUSE

DAMAGE TO FRICTION MATERIAL WHICH

MAY RESULT IN BRAKE FAILURE AND

LOSS OF LOAD CONTROL.