24

309150

Maintenance

I.

Shut down machine and allow to cool for approximately 10 minutes.

II.

Verify entire system pressure is relieved before proceeding.

III.

Remove both heads, cylinders, and pistons. See Piston Ring Replacement on P. 21.

IV.

Remove the bolts on the connecting rods, and lift them out. Reassemble the connecting rods to be

certain that the matched parts remain together on the same crankshaft journals.

V.

Remove the pump cover, oil pump, sleeve, spring, and rear bearing housing.

VI.

Remove the drive hub, and the front bearing housing.

VII.

Pull the crankshaft from the crankcase.

VIII.

Remove all gasket material with a single edged razor blade, or sharp putty knife.

VIII.

Place the pump cover into position and start two bolts (bolts must be diagonally opposed). Strike

the pump cover with a rubber faced mallet to jar the pump loose. When the tension spring can be

felt against the pump cover, the pump is loose.

IX.

Insert the two remaining bolts and torque to 180 in-lbs. The bolts should be torqued in a diagonal

pattern.

X.

Install the air compressor in the vehicle. Connect the air lines and wiring.

3. Crankshaft and Bearing Replacement

If it is necessary to replace the crankshaft, related components must also be replaced. Replace both

bearings, both races, the key, pump collar and pump drive pin.

Depending on the condition of the crankshaft, bearing may be replaced

without replacing the crankshaft. Replace the bearing races whenever the

bearings are replaced.

Do not allow the gasket material to fall into the crankcase. Do not nick

the head, cylinder, or crankcase mating faces while removing the old

gasket. Remove all of the old gasket material to provide a smooth,

clean surface for the new gasket. Failure to follow this procedure may

result in the need to reseal the unit later.

IX.

Press the bearing races out of the bearing housing.

Do not gouge the machined surfaces when removing the gaskets. This may

cause leaks.

Summary of Contents for 36 BHP PISTON

Page 2: ...2 309150 ...

Page 28: ...28 309150 ...

Page 29: ...29 309150 WARRANTY SECTION ...

Page 34: ...34 309150 ...

Page 35: ...35 309150 PARTS AND ILLUSTRATION SECTION ...

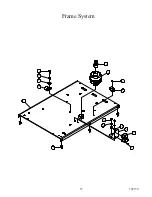

Page 37: ...37 309150 16 15 13 14 10 1 2 5 11 12 8 6 7 9 4 3 Frame System ...

Page 43: ...43 309150 13 6 5 3 7 1 4 4 2 10 11 12 9 8 16 14 15 16 Cooler System ...

Page 45: ...45 309150 3 1 10 7 2 4 6 5 13 12 11 9 8 Hydraulic Drive System ...

Page 47: ...47 309150 2 3 4 6 5 1 7 Discharge System ...

Page 49: ...49 309150 Canopy System 11 13 4 6 7 1 12 2 2 8 3 4 10 9 5 ...

Page 51: ...51 309150 2J 2B 2C 2D 2J 2H 2E 1 2I 2G 2A 2F Decal System ...

Page 52: ...52 309150 System Schematic ...