6

6 720 606 692 (02.05)

4.4

Maintenance

When it has been in service for a year, the appliance

should be inspected, thoroughly cleaned and, if

necessary, descaled.

Servicing may only be carried out by an authorised person.

Before carrying out maintenance work of any kind, the gas

and cold water isolating cocks must be turned off.

Heat Exchanger body

Clean the flue side of the heat exchanger block. Check

heat exchanger body and connecting pipes for scale and if

necessary descale with proprietary descaler according to

manufacturers instructions.

The descaling is done only to the heat exchanger, the

chemicals used damage the HDG and other parts.

Test for leaks at max. 2000 kPa.

Use new gasket when re-assembling.

Burner

Unscrew burner and clean in soap solution if necessary.

Pilot burner

The flame should heat the flame-failure electrode (diagram

3, item 4). If the flame is too small, clean pilot burner.

Slow ignition valve

After unscrewing the valve, clean out any dirty particles.

The ball inside the valve must move freely (check by shaking).

Inspect the O-ring and replace if necessary. Screw the slow

ignition valve back in. Check all connections for leaks.

Checking the vacuum chamber

-

Push the sliding gas control to the right and draw off hot

water.

-

Disconnect green lead from the servo gas valve (diagram

3, item 1). The main burner should go out and the pilot

burner remains lit. Disconnect the red lead from the pilot

gas valve (diagram 3, item 3) - the pilot flame should

then go out.

-

Re-connect red lead, pilot burner should re-ignite.

-

Re-connect green lead, main burner should re-ignite.

Functional Test

(does not apply to first time commissioning).

Switch off appliance. When a hot water tap is turned on,

the burner should come on full within 5 seconds. When the

hot water tap is turned off, the burner should go out within

approximately 2 seconds.

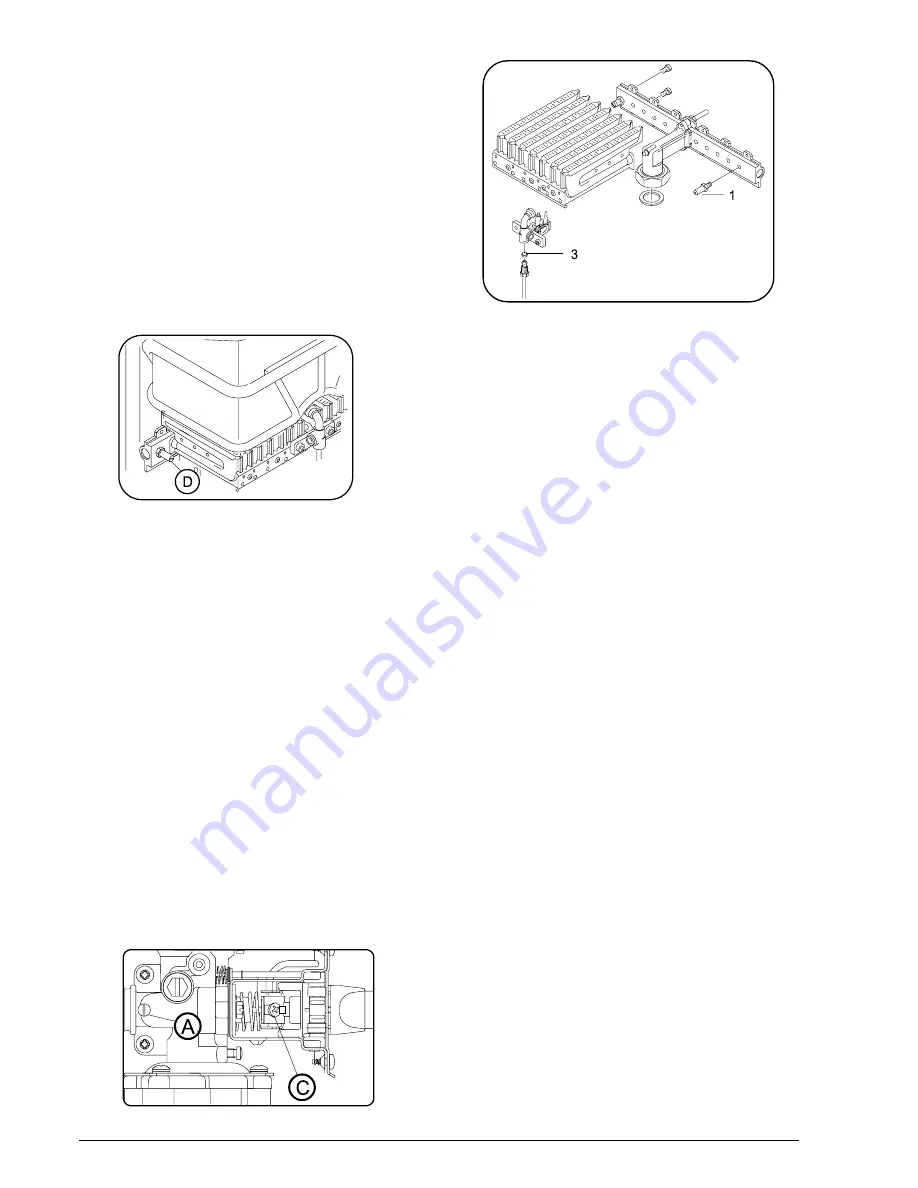

Diagram 7

G661_009

G661_016

Diagram 6

4.3

Conversion to Other Gases

Only use conversion kits supplied by the manufacturer.

This operation must be carried out by a qualified fitter.

1. Cut off the gas supply by closing the gas isolating valve,

and remove the front cover of the appliance;

2. Remove the burner and replace the injectors (diagram 7,

item 1);

3. Replace the pilot gas injector (diag. 7, item 3);

4. Replace the vacuum chamber if converting from LP to

NG. Pressure regulator also required.

5. Replace the main poppet valve head (diag.2, item 27);

6. Tighten the gas valve and check for possible leaks;

7. Note the new type of gas on the appliance's rating plate;

8. Finally, adjust the minimum gas flow of the appliance

using a suitable method, the most common one being

described below:

a) Select a manometer with a mbar or mm (H

2

O) scale;

b) Loosen sealing screw D in the burner pressure tap-off

point (diagram 5) and connect the manometer;

c) Open the gas isolating valve;

d) Start up the appliance with the output slide control at

the minimum output position;

e) Adjust the pressure using screw C (diagram 6), in

compliance with Section 2 Technical Data, page 4.

G662_042

Diagram 5

Gas burner pressure adjustment for minimum output

(see clause 4.3, section 8)

Gas inlet pressure adjustment

1.

Turn off gas supply.

2.

Remove inlet test point screw A.

3.

Attach U tube manometer.

4.

Turn on gas supply and start up appliance in accordance

with operating instructions.

5.

Check inlet gas pressure while appliance is operating.

6.

For natural gas appliances adjust pressure at appliance

regulator.

No adjustment for LP appliances, check cylinder

regulator and pipe size.

7.

Turn off gas supply, remove manometer, replace sealing

screw, turn on gas supply and test for leaks.