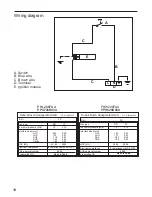

A range hood fitted above the top must be installed

according to the installation instructions for the range

hood. A minimum distance of 650 mm is required for a

range hood and 750 mm for an exhaust fan.

Minimum thickness of benchtop is 30 mm. See Fig. 2.

Installation procedure:

Clearances

2

Installation of

cooktop into the

kitchen bench

30 mm

minimum

Any adjoining wall surface situated within 200mm from the

edge of any hob burner must be a suitable non-com-

If the base of the hotplate can be touched, a protecting

shield must be fitted. This shield must be at least

10mm from the lowest part of the hotplate and must

be capable of withstanding the appliance temperatures.

bustible

material for a height of 150mm for the entire

length of the hob. Any combustible construction above

the hotplate must be at least 650mm above the top of

the burner and no cons

above the top of the

truction shall be

within 4 50mm

.

burner

A minimum depth of 50mm from the top of the

worktop

surface must be provided for the a

ppliance.

1. For cutout dimensions and clearances refer

2.

a) If the clamps and the selfadhesive seal (lower edge

of the hob) are already fitted (depending on the model),

keeps the entire work surface watertight and prevents

spilage from leaking into cupboards underneath. Slightly

do not under any circumstance remove them. The seal

losen the retaining screws of the clamps positioned at

the bottom of the cooktop.

b ) If the clamps and the selfadhesive seal have not

the gas burner covers from your cooking hob and turn it

upside down. Now fit the selfadhesive seal supplied

with the appliance onto the lower edge of the hob. Take

the clamps and screw them into the lower point designed

been fitted in the factory, remove the pan support and

for this purpose. See Fig. 3.

Side clearances: If the distance measured from the

periphery of the nearest burner to any vertical surface

is less than 200 mm, the surface shall be protected in

accordance with clauses 5.12.1.1 & 5.12.1.2 of AS 5601.

Fig.1

.

7