Operation

Greenstar FS/Combi FS – 6720810589 (2021/01)

14

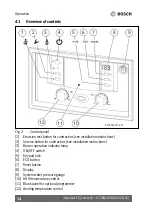

4.1

Overview of controls

0010026577-001

1

2

3

4

5

6

7

8

9

12

10

11

Fig. 2

Control panel

[1]

Emission test button for contractors (see installation instructions)

[2]

Service button for contractors (see installation instructions)

[3]

Burner operation indicator lamp

[4]

ON/OFF switch

[5]

Key pad lock

[6]

ECO button

[7]

Reset button

[8]

Display

[9]

System water pressure gauge

[10] DHW temperature control

[11] Blank panel for optional programmer

[12] Heating temperature control