-10-

Operating Instructions

VARIABLE SPEED CONTROLLED

TRIGGER SWITCH

Your tool is equipped with a variable speed

trigger switch. The tool speed can be

controlled from the minimum to the maximum

nameplate speed by the pressure you apply

to the trigger. Apply more pressure to

increase the speed and release pressure to

decrease speed. This accurate speed control

enables you to drill without center punching.

It also permits you to use as a power

screwdriver. Bits are available for driving

screws as well as running bolts and nuts.

REVERSING SWITCH LEVER

This tool is equipped with a rotating brush

reversing system. This results in longer brush

life while maximizing power in both forward and

re verse directions. The reverse switch can be

oper ated from either the right or left side of the

tool.

FOR FORWARD ROTATION: slide switch to

arrow marked forward (Fig. 1).

FOR REVERSE RO TATION: slide the slide

switch to arrow marked re verse. NOTE: Tool

will not operate in middle position.

SLIP CLUTCH

The tool has an internal preset clutch. The

clutch is set such that sufficient force is

transmitted to the bit for most drilling

conditions but it will slip when bit binds in the

hole or the tool is overloaded. Be aware that

due to required clutch setting, you may

experience a torque reaction an instant

before the clutch slips. This torque reaction

will twist the body of the rotary hammer in the

opposite direction as the bit rotates, i.e.,

counterclockwise. As clutch is slipping, the

bit will most likely stop rotating. When the

binding force on the bit is removed the clutch

automatically resets. If you experience bit

binding and clutch begins to slip, immediately

turn the tool "OFF" and correct the condition

leading to the bit binding.

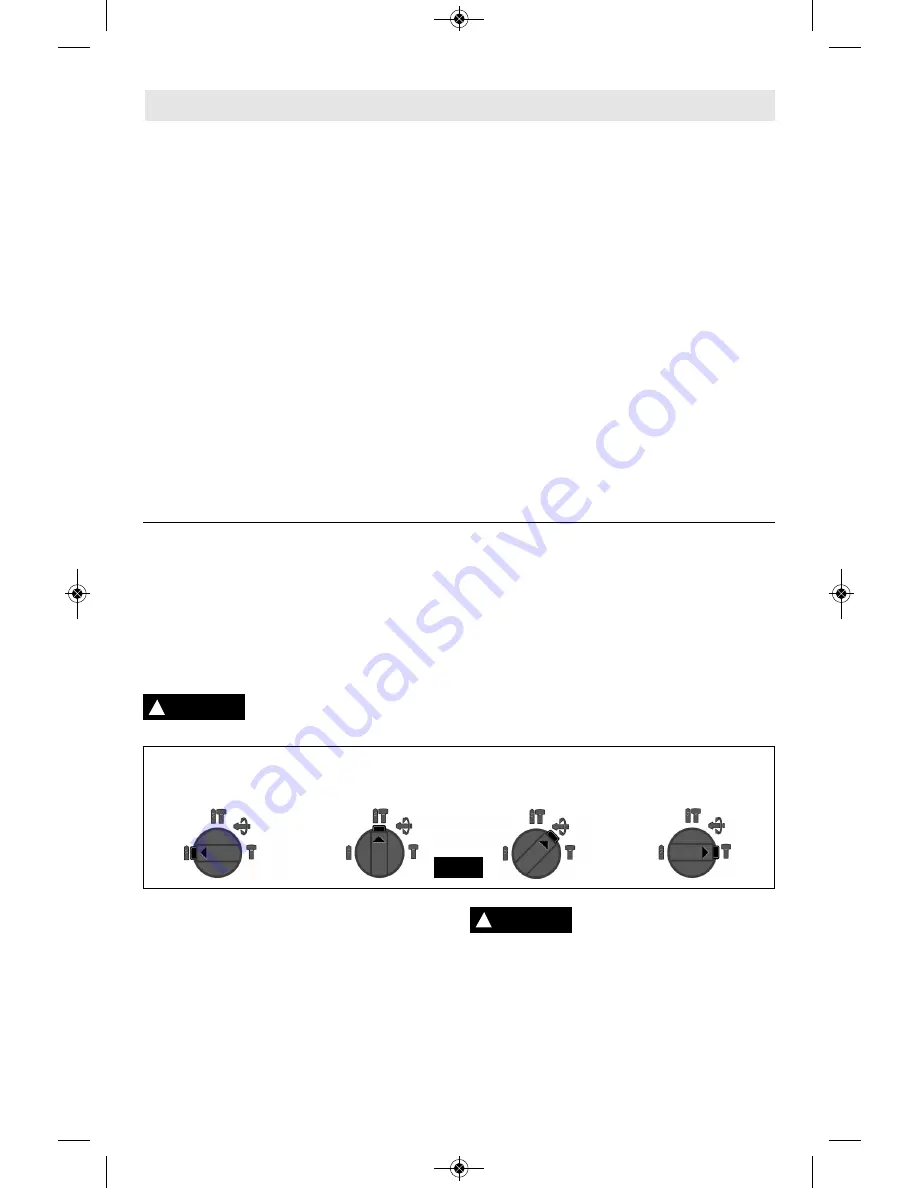

SELECTOR DIAL

The selector dial allows the tool to be set for

various drilling/hammer drilling applications.

Depress release button and turn selector dial

right or left depending on the below applications.

When using demolition or chipping bits such as

bull points, chisels, spades, gouges, etc. the

“Hammer Only” mode must be selected.

Do not operate the selection dial until the

tool come to a complete

stop.

Shifting during rotation of

the chuck can cause damage to the tool.

SELECTOR DIAL - “VARIO-LOCK”

Adjusting the Vario-Lock: The vario-lock

can be set in any one of thirty-six (10˚

increments) positions. Choose a position

which is best suited for your operation.

Depress release button and turn the selector

dial, to the “vario-lock” setting. Next, rotate

the locking sleeve, along with the accessory,

to the desired position. Then turn the selector

dial to the “hammer only” setting and slightly

turn the locking sleeve to have it

automatically lock into a definite position.

!

CAUTION

Drilling only: Drilling/hammering: Vario-lock Hammering only:

used for drilling

used for drilling allows for 36 desired used for light

wood, steel, etc. concrete positions of “hammer” chipping work

FIG. 6

HAMMERHOOK

™

(Model 11255VSR & RH226 only)

Your tool is equipped with a convenient hook

for hanging your tool. To use, simply open hook

until it snaps into the open position (Fig. 7).

When using the HAMMERHOOK™ always

be aware that the accessory is exposed.

Always hang the tool in an area where

yourself and bystandards can not accidently

make contact with the accessory.

To reduce the risk of

injury,

use

care

in

selecting the location for hanging the

tool.

• Select a suitably sized and shaped object

that will provide adequate hanging stability.

An unstable hanging surface could result in

the tool unexpectedly falling.

• Insure that the tool is hung out of the way of

!

WARNING

2610047983_11253VSR 10/2/17 1:10 PM Page 10