235

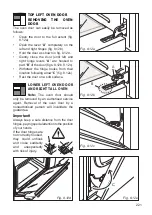

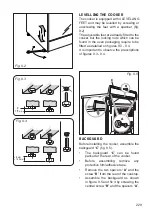

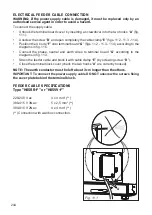

The group of attachments (fig. 10.3) is

made up of:

• 1 nut “

A

” ( external cylindrical thread

ISO 228-1)

• 1 sealing washer “

D

”

• 1 conical connection “

B

” (internal

cylindrical thread ISO 228-1, external

conical thread ISO 7-1)

• 1 Butane/Propane Gas connector “

C

”.

Exception for single unit cookers that

are not built-in.

• These cookers must be connected by

a flexible elastomer hose with a built–in

undetachable mechanical nozzle. Only use

those hoses that are authorised with the

label “AGB/BGV”.

• Two types of flexible elastomer hoses: until

April 2005, there were 2 types of flexible

elastomer hoses on the market:

- the old assymetrical model, including an

end with a fixed nozzle at the side of the

cooker, and a nozzle with a loose nut

and a built-in flat sealed joint at the side

of the inside fitting (stop cock) .

- the new symmetrical model, including a

nozzle with a loose nut at both sides,

with a built-in flat sealed joint. This

symmetrical model is the only one that

will be available after the time limit.

When installing a new cooker, or replacing

an existing one, the symmetrical model must

always be used.

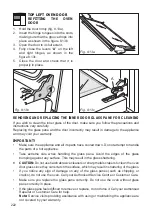

Assembly

The gas inlet on the old cookers is equipped

with a conical thread ISO 7-1 – and the hose

is assembled as follows:

1. apply a sealing product to the thread on

the appliance: a strip of teflon or sealing

paste for threads (colmat) plus some

acrylic wool;

2. tighten up the linking component (the

cylindrical inside thread ISO 7-1 to the

cylindrical ouside thread ISO 228-1) with

the two keys on the cooker;

3. check that the sealed joint is firmly

inserted inside the moveable connection

on the elastomer hose (new model);

4. tighten up by hand the elastomer hose on

both sides;

5. tighten up with a spanner;

6. open the stop cock and check that there

are no leaks (soap bubbles) by smearing

on a frothing product ).

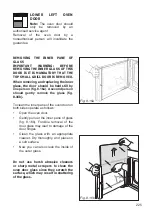

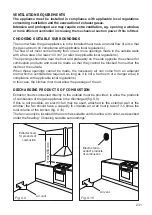

Cookers must be connected using R

HT

materials downstream from the AGB/

BGV certificated gas stop-cock, except for

single unit cookers that are not built-in.

As a general rule, cookers are connected

downstream from the gas stop-cock, by:

• copper pipes having an appropriate wall

thickness, or;

• steel pipes, or;

• flexible R

HT

metal pipes with AGB

certification, fitted in such a way that

they will not be crushed or pulled

during use. Their bending radius must

not be less than that specified by the

manufacturer.

D

D

B

C

Fig. 10.3

A

BE

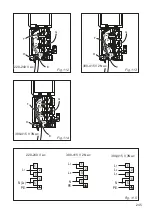

Summary of Contents for CFBG903AN

Page 35: ...35 S F C T A B Afb 8 1 Afb 8 2 Afb 8 3 Afb 8 4 Afb 8 5 T S ...

Page 62: ...62 ...

Page 96: ...96 S F C T A B Abb 8 1 Abb 8 2 Abb 8 3 Abb 8 4 Abb 8 5 T S ...

Page 123: ...123 ...

Page 157: ...157 S F C T A B Fig 8 1 Fig 8 2 Fig 8 3 Fig 8 4 Fig 8 5 T S ...

Page 185: ...185 ...

Page 217: ...217 S F C T A B Fig 8 1 Fig 8 2 Fig 8 3 Fig 8 4 Fig 8 5 T S ...

Page 246: ...246 ...

Page 247: ...247 ...

Page 248: ...Abberdaan 114 1046 AA Amsterdam The Netherlands www boretti com Cod 1105653 ß0 ...