507266-04B

Page 51 of 56

Issue 1904

Turning Off Gas to Unit

1. Set the thermostat to the lowest setting.

2. Turn off all electrical power to the unit if service is to

be performed.

3. Remove the upper access panel.

4. Move gas valve switch to OFF.

5. Replace the upper access panel.

Failure to Operate

If the unit fails to operate, check the following:

1. Is the thermostat calling for heat?

2. Are access panels securely in place?

3. Is the main disconnect switch closed?

4. Is there a blown fuse or tripped breaker?

5. Is the filter dirty or plugged? Dirty or plugged filters will

cause the limit control to shut the unit off.

6. Is gas turned on at the meter?

7. Is the manual main shut–off valve open?

8. Is the internal manual shut–off valve open?

9. Is the unit ignition system in lockout? If the unit locks

out again, inspect the unit for blockages.

Heating Sequence of Operation

1. When thermostat calls for heat, combustion air inducer

starts.

2. Combustion air pressure switch proves blower

operation. Switch is factory set and requires no

adjustment.

3. After a 15 second pre-purge, the hot surface ignitor

energizes.

4. After a 20 second ignitor warm-up period, the gas

valve solenoid opens.

5. Gas is ignited, flame sensor proves the flame, and the

combustion process continues.

6. If flame is not detected after first ignition trial, the

ignition control will repeat steps 3 and 4 four more

times before locking out the gas valve. The ignition

control will then automatically repeat steps 1 through

6 after 60 minutes. To interrupt the 60 minute period,

move thermostat from “Heat” to “OFF” then back to

“Heat”. Heating sequence then restarts at step 1.

Gas Pressure Adjustment

Gas Flow (Approximate)

Capacity

Seconds for One Revolution

Natural

LP

1 cu ft

Dial

2 cu ft

Dial

1 cu ft

Dial

2 cu ft

Dial

-70

55

110

136

272

-90

41

82

102

204

-110

33

66

82

164

Natural - 1000 btu/cu ft

LP - 2500 btu/cu ft

Table 13. Gas Meter Clocking Chart

Furnace should operate at least 5 minutes before checking

gas flow. Determine time in seconds for two revolutions of

gas through the meter. (Two revolutions assures a more

accurate time.) Divide by two and compare to time in Table

13. If manifold pressure matches Table 12 and rate is

incorrect, check gas orifices for proper size and restriction.

Remove temporary gas meter if installed.

NOTE:

To obtain accurate reading, shut off all other gas

appliances connected to meter.

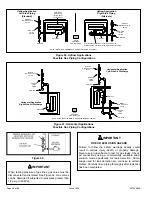

Supply Pressure Measurement

An inlet pressure post on the inlet side of the gas valve

provides access to the supply pressure. See Figure 74.

Back out the 3/32 Hex screw one turn, connect a piece

of 5/16” tubing and connect to a manometer to measure

supply pressure.

NOTE:

Shut unit off and remove manometer as soon as

an accurate reading has been obtained. Take care to re-

tighten the 3/32 Hex screw.

Capacity

Natural to LP/

Propane

High Altitude Natural

Burner Orifice Kit

High Altitude LP/

Propane Burner

Orifice Kit

High Altitude Pressure Switch

0 - 7500 ft

(0 - 2286m)

7501 - 10000 ft

(2286 - 3048m)

7501 - 10000 ft

(2286 - 3048m)

4501 - 7500 ft

(1371 - 2286m)

7501 - 10000 ft

(2286 - 3048m)

070

11K48

*51W01

11K47

14A54

14A53

090

14A57

14A54

110

14A46

14A51

*Conversion requires installation of a gas valve manifold spring which is provided with the gas conversion kit.

Pressure switch is factory set. No adjustment necessary. All models use the factory-installed pressure switch from 0-4500 feet (0-1371 m).

Table 14. Conversion Kit Fan Pressure Switch Requirements at Varying Altitudes