520-319-000 Air Operated Double Diaphragm Pump 11/01

PUMPING HAZARDOUS

LIQUIDS

When a diaphragm fails, the

pumped liquid or fumes enter the

air end of the pump. Fumes are

exhausted into the surrounding

environment. When pumping haz-

ardous or toxic materials, the ex-

haust air must be piped to an ap-

propriate area for safe disposal. See

illustration #1 at right.

This pump can be submerged if

the pump materials of construction

are compatible with the liquid being

pumped. The air exhaust must be

piped above the liquid level. See

illustration #2 at right. Piping used

for the air exhaust must not be

smaller than 1" (2.54 cm) diameter.

Reducing the pipe size will restrict

air flow and reduce pump perfor-

mance. When the pumped product

source is at a higher level than the

pump (flooded suction condition),

pipe the exhaust higher than the

product source to prevent siphon-

ing spills. See illustration #3 at right.

IMPORTANT INSTALLATION

NOTE:

The manufacturer recom-

mends installing a flexible hose or

connection between the pump and

any rigid plumbing. This reduces

stresses on the molded plastic

threads of the air exhaust por t.

Failure to do so may result in

damage to the air distribution valve

body.

Any piping or hose connected to

the pump’s air exhaust port must be

physically supported. Failure to

support these connections could

also result in damage to the air

distribution valve body.

SAFE AIR

EXHAUST

DISPOSAL

AREA

PUMP INSTALLATION AREA

1" DIAMETER AIR

EXHAUST PIPING

SILENCER

CONVERTED EXHAUST ILLUSTRATION

Illustration #1

Illustration #2

Illustration #3

1" DIAMETER AIR

EXHAUST PIPING

LIQUID

LEVEL

SUCTION

LINE

SILENCER

1" DIAMETER AIR

EXHAUST PIPING

LIQUID

LEVEL

SUCTION

LINE

SILENCER

Page 10

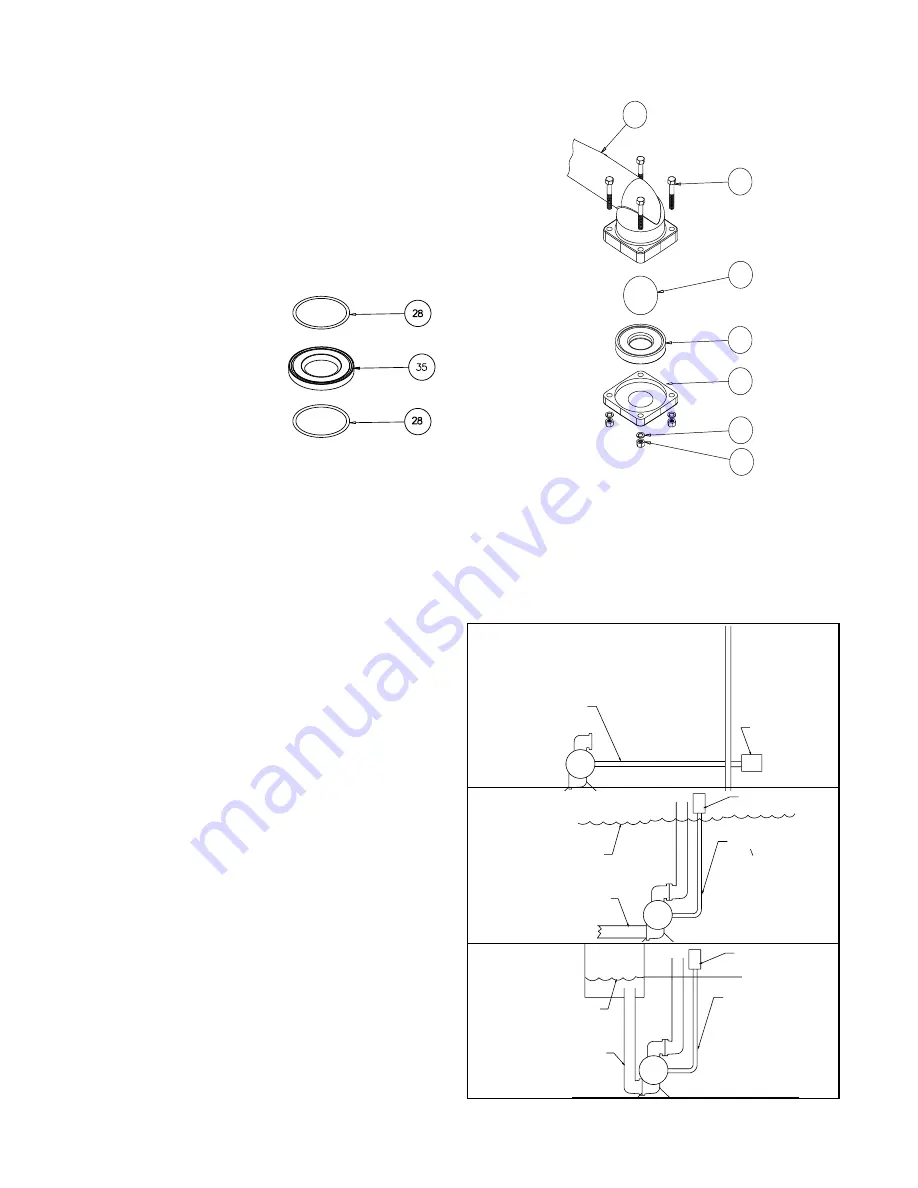

Check Valve Drawing

CHECK VALVE SERVICING

Before servicing the check valve

components, first shut off the

suction line and then the discharge

line to the pump. Next, shut off the

compressed air supply, bleed air

pressure from the pump, and dis-

connect the air supply line from the

pump. Drain any remaining fluid from

the pump. The pump can now be

removed for service.

To access the check valve

components, remove the manifold

(item 23 or item 22 not shown). Use

a

5

/

8

" &

11

/

16

" wrench or socket to re-

move the fasteners. Once the mani-

fold is removed, the check valve

components can be seen.

Inspect the check balls (items 2)

for wear, abrasion, or cuts on the

spherical surface. The check valve

seats (item 35) should be inspected

for cuts, abrasive wear, or embed-

ded material on the surfaces of both

the external and internal chambers.

The spherical surface of the check

balls must seat flush to the surface

of the check valve seats for the pump

to operate to peak efficiency.

Replace any worn or damaged parts

as necessary.

Reassemble the check valve

components. The seat should fit

into the counter bore of the outer

chamber.

23

10

2

35

14

36

25

with Non-Metallic

Seats

with Metallic Seats

The pump can now be reas-

sembled, reconnected and returned

to operation.

METALLIC SEATS

Two o-rings (or seals) (item 28)

are required for metallic seats.

Summary of Contents for B75

Page 2: ......