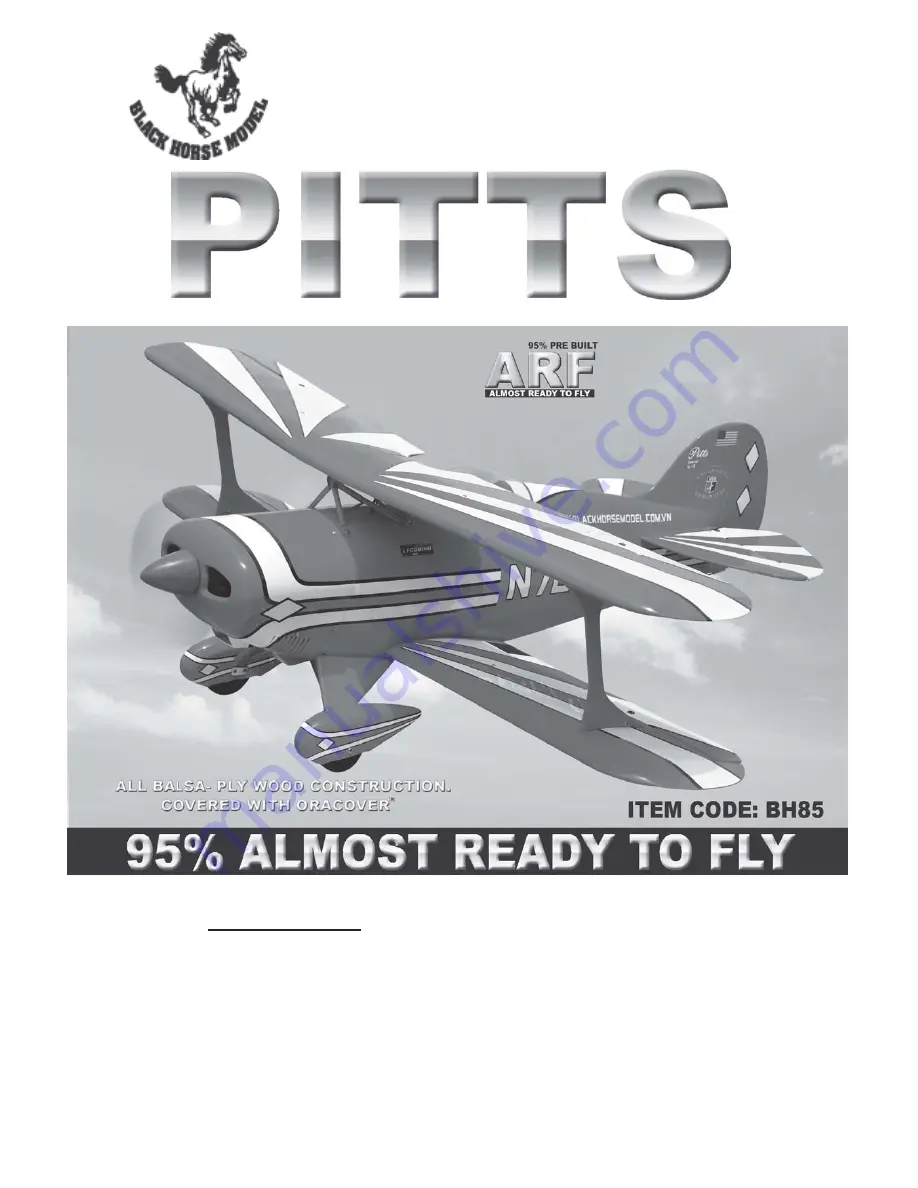

SPECIFICATION

Wingspan : 1.500 mm 59.06 in.

Length : 1.330 mm 52.36 in.

Weight : 4.7 kg 10.34 Lbs.

Radio : 6 channels.

Servo : 7 servos.

Engine : 120 2stroke.

Instruction Manual book

Made in Vietnam.