17

Part description

Quantity per pump

Impeller

1 piece

Shaft Seal

1 set

Bottom Plate

1 piece

Packing

Full set

8) Overhauling procedure (refer to section 11 “Sectional Drawing”).

•

Perform the overhauling work with the pump kept in horizontal position.

•

Unscrew off the bolts (B1 in Sectional DWG) to separate the pump

from the pump base (170). Then, lift up the pump using the lifting eye-

bolt (58).

•

Provided two wooden blocks of about 100mm square onto clean floor

and put the pump thereon horizontally.

•

By this, the pump is ready for overhaul. Overhaul the pump in the

procedure given below.

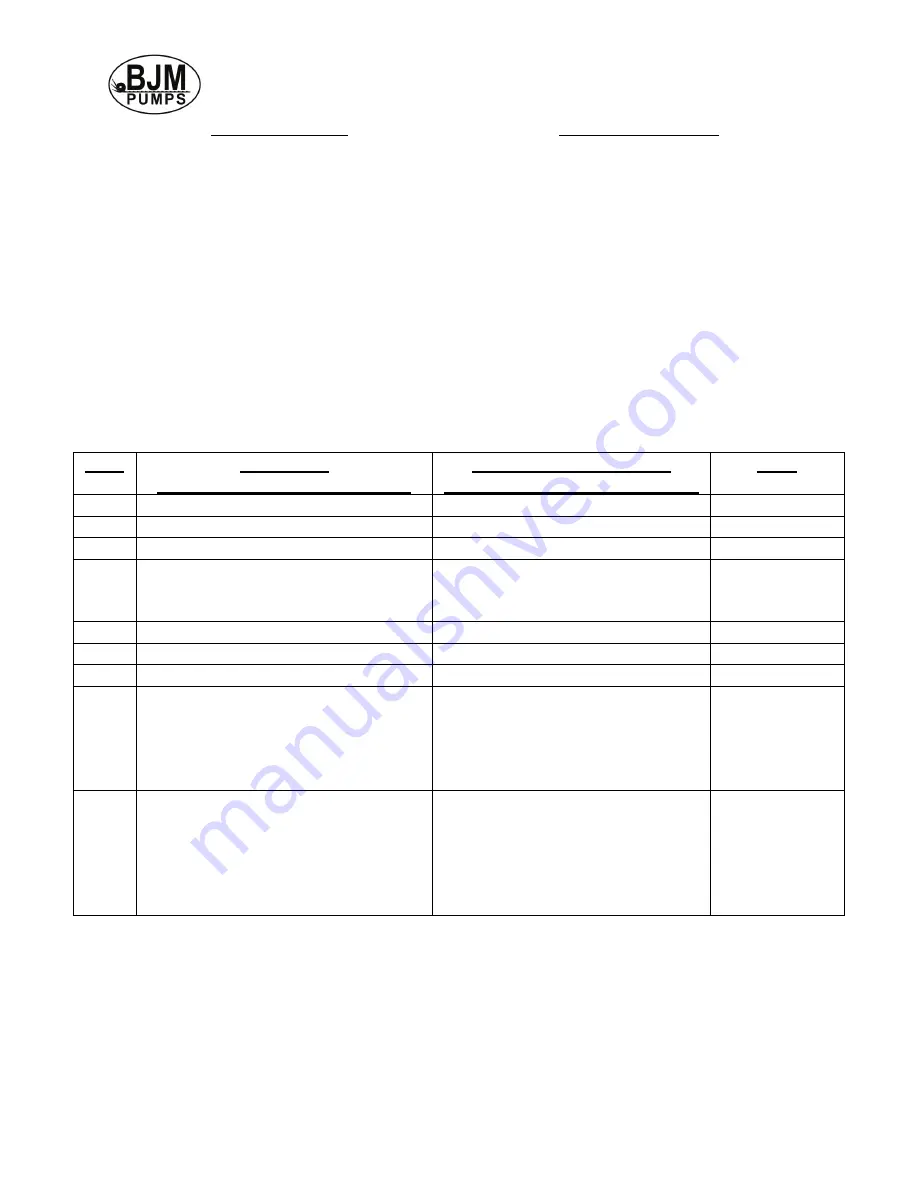

Step

Part Name

( ) : part No. in sectional DWG

Overhauling Procedure

( ): Part No. in sectional DWG.

Note

1

Strainer (16)

Unscrew off stud nut (SN1)

2

Bottom Plate (15)

Unscrew off stud-nut (SN2)

3

Impeller nut (B2)

Unscrew off the nut

4

Impeller (14)

Draw off the shaft from shaft (8).

Be careful not

to damage the

vanes

5

Casing (13)

Unscrew off stud nut (SN3)

6

Drain-out of oil

Remove oil plug (28)

Follow 5.1 (1)

7

Lower oil box (12L)

Unscrew off stud nut (SN4)

8

Shaft seal (10)

After removal of the lower oil

box (12L) in step 7, mechanical

seal parts appear. Pull them out

one by one from the shaft using

a hooked-shaped puller.

9

Upper oil box (12U) and rotor (7)

Unscrew off stud nut (SN5)

In this case,

be careful not

to damage

stator coil,

shaft and

bearing.

Summary of Contents for PGV 110

Page 2: ......

Page 19: ...19 SECTIONAL VIEW OF PGV55 75 110...

Page 20: ...20 SECTIONAL VIEW OF PGV220...

Page 27: ...NOTES...

Page 28: ......

Page 29: ......