CB-100-1

60

5.6

Safe Torque Off (STO)

As standard, the VARIPACK frequency inverters are

equipped with a certified and safety-tested shut-off

function, Safe Torque Off (STO).

• The STO function ensures that no torque-generating

energy can act any more on the compressor motor.

This will prevent an unexpected start according to

EN 60204-1 Section 5.4.

• The STO function safely deletes all pulses of the

drive. The drive is safely free of torque. This state is

monitored inside the drive.

• The STO function allows the main contactor up-

stream or downstream of the VARIPACK to be omit-

ted. Instead of being switched as before via the main

contactor, the STO, switched via the high-pressure

switch or other safety-relevant protective functions,

can shut off the compressor directly.

DANGER

The STO function is not a galvanic isolation and

may therefore not be used for maintenance or

repair work!

It is only an electronic protective function during

normal operation of the VARIPACK frequency

inverter.

Prior to performing maintenance or repair work,

the VARIPACK must be completely disconnec-

ted from the mains supply using a suitable elec-

trical disconnecting device and proper isolation

of all voltage connections must be checked!

Switch off the main switch and secure it against

being switched on again.

Wait for at least 5 minutes until all capacitors

have been discharged!

Information

The STO function is a factory built-in and tested

function.

Repairs on VARIPACK frequency inverters

equipped with STO function may only be carried

out authorized staff.

Any unauthorized attempt to repair or dismantle

the VARIPACK will void the guarantee and may

impair the STO function.

As soon as the VARIPACK frequency inverter

will detect an internal STO error, it must be elim-

inated immediately.

!

!

NOTICE

Defined switching points are no longer guaran-

teed if lines are too long or incorrectly installed.

Maximum line length to terminals X10/01,

X10/03, X10/05 and X10/06: 25 m!

Install lines only inside the switch cabinet or the

FI housing!

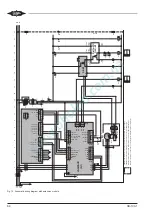

• For high safety requirements, two independent STO

control channels have been implemented in the

hardware. The STO circuit is designed such that

upon occurrence of an error in a channel, the second

channel ensures that no inadvertent operation of the

VARIPACK frequency inverter takes place.

• The activated STO function overrides all attemps to

start the compressor. This means that if the STO

function is switched by one or both STO control in-

puts, the compressor will not start. This is also true

if, for example, an internal software error should res-

ult in a start attempt.

Safety specifications:

According to EN ISO13849-1 and EN 61800-5-2, the

VARIPACK frequency inverters have the following

safety characteristics:

Safety level reached by the frequency inverters

①

SIL

Safety integrity level

SIL3

PL

Performance level

PLe

Underlying safety characteristics ②

PFH

Probability of dangerous

failures per hour

2,3 x 10

-9

MTTF

d

Mean time to dangerous

failure

100 years

③

DC

Diagnostic coverage

98.6% →

high

SFF

Safe failure fraction

99% → av-

erage

T

M

Mission time

20 years

Tab. 5: VARIPACK safety characteristics according to EN

ISO12849-1 and EN 61800-5-2

①: The indicated safety levels and the respective

safety characteristics are applicable for the VARIPACK

frequency inverter if both STO inputs can be activated

independently of each other. Depending on the integra-

tion into the system, the safety level of the complete

system can be lower and must be calculated by the

system manufacturer.

Summary of Contents for VARIPACK FDU+12

Page 12: ...CB 100 1 12 1 2 3 4 Abb 7 Steuremodul abmontieren...

Page 46: ...CB 100 1 46 1 2 3 4 Fig 7 Dismounting the control module...

Page 70: ...Notes...

Page 71: ...Notes...