CT-110-2

9

• the SE-i1 is retrofitted.

• the SE-i1 as a replacement for SE-C1 is upgraded to

the full functionality of the SE-i1.

5.1.1

Mounting of the pressure transmitter to CS.

compressors

During all mounting work:

WARNING

The compressor is under pressure!

Serious injuries are possible.

Depressurize the compressor!

Wear safety goggles!

Connection positions see table 2, page 9.

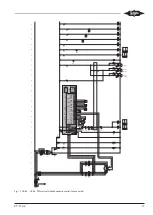

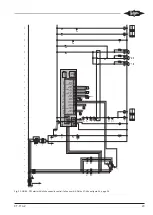

The following drawings show the connection positions

and the mounting using a CS.95 compressor as an ex-

ample. The positions of the connections 2 (LP) and 3

(LP) can vary, depending on the compressor. For

CS.65 .. CS.85, see dimensional drawings in the bro-

chures SP-171 (CSH) and SP-172 (CSW).

For the CSHP compressors, the SE-i1 is delivered sep-

arately as a basic sensor kit (part number 347 050 02).

It must be installed, wired and connected in the sys-

tem's switch cabinet, The cables between compressor

and switch cabinet must be protected by a fuse in the

terminal box. The fuse layout depends on the cable

cross-section and the applicable application-related

standards and can therefore not be universally spe-

cified.

High pressure transmitter

• First, screw in the T-piece into the connection posi-

tion 2 (HP) at the compressor.

• Then, screw the high pressure transmitter to the T-

piece and connect the sensor cable.

7/16-20 UNF

1 (HP)

1/8-27 NPTF

2 (HP)

Fig. 3: CS.95 compressor: Mounting of the high pressure transmitter

Connection positions CS. compressors

1

High-pressure connection (HP)

2

Additional high pressure connection (HP).

Connection for high pressure transmitter

3

Low pressure connection. Connection for low

pressure transmitter

4/8

Oil sight glass / connection for opto-electronic

oil level switch (OLC-D1-S)

5

Oil service valve

12

Oil temperature sensor (PTC)

Tab. 2: Connection positions CS. compressors, pressure transmitters

and NTC sensor

Summary of Contents for SE-i1

Page 54: ...Notes...

Page 55: ...Notes...