(10) BISSELL BigGreen Commercial FMT Dual-Speed Floor Machine

BISSELL BigGreen Commercial FMT Dual-Speed Floor Machine (11)

5.0 Troubleshooting Guide

Never operate this floor machine when the equipment is not performing as expected

or when any part is visibly damaged. The cause and solution for some basic problems

are described below. When repair is needed, take the equipment to an authorized repair

service center.

5.1 The Floor Machine will not Run

• Circuit breakers are tripped in the building.

Check and reset.

• Equipment is unplugged.

Check plug, wall and at machine base. Plug in.

• Power cord failure.

Test with a working power cord. Lock the handle up and tip the

motor back. Unplug the cord at the motor and plug the motor into your working

power cord.

• IMPORTANT! THIS IS JUST FOR TESTING. When you do this, you have

removed the safety handle controls from the circuit and you are sending power

directly to the motor. If the motor now spins, the problem is in the cord of the

handle assembly. Seek authorized repair services.

• If the motor still does not spin, the problem is either in the male connection at the

motor base or in the motor. Seek authorized repair service.

• Motor sparks or smokes.

Seek authorized repair service.

5.2 Electrical Shock to Operator

• Equipment wiring failure or electrical short in the machine.

Seek authorized service.

• Poor grounding or no grounding.

Test the outlet with a ground fault interrupter.

Retain certified electrician to inspect and repair grounding. NEVER clip off the

ground plug on your cord.

• Repeated circuit breaking.

High amp draw and circuit breaking can be an electrical

or mechanical problem. Seek authorized repair service.

5.3 High Vibration

• Pads are not centered on the pad driver.

Tip machine back and re-center the pad.

• Uneven wear or warp of pads, pad drivers or brushes.

Replace.

• Machine chassis is damaged by dropping.

Replace.

4.2 Transport

To transport this floor machine from the janitor’s closet

to the work area:

• Lock the handle in the “up” position. Wid the cord

around the handles and the bottom cord hook.

• Tip the machine back onto the transport wheels. Push

or pull the machine by the handle, not by the cord or

any other part of the machine. Travel carefully.

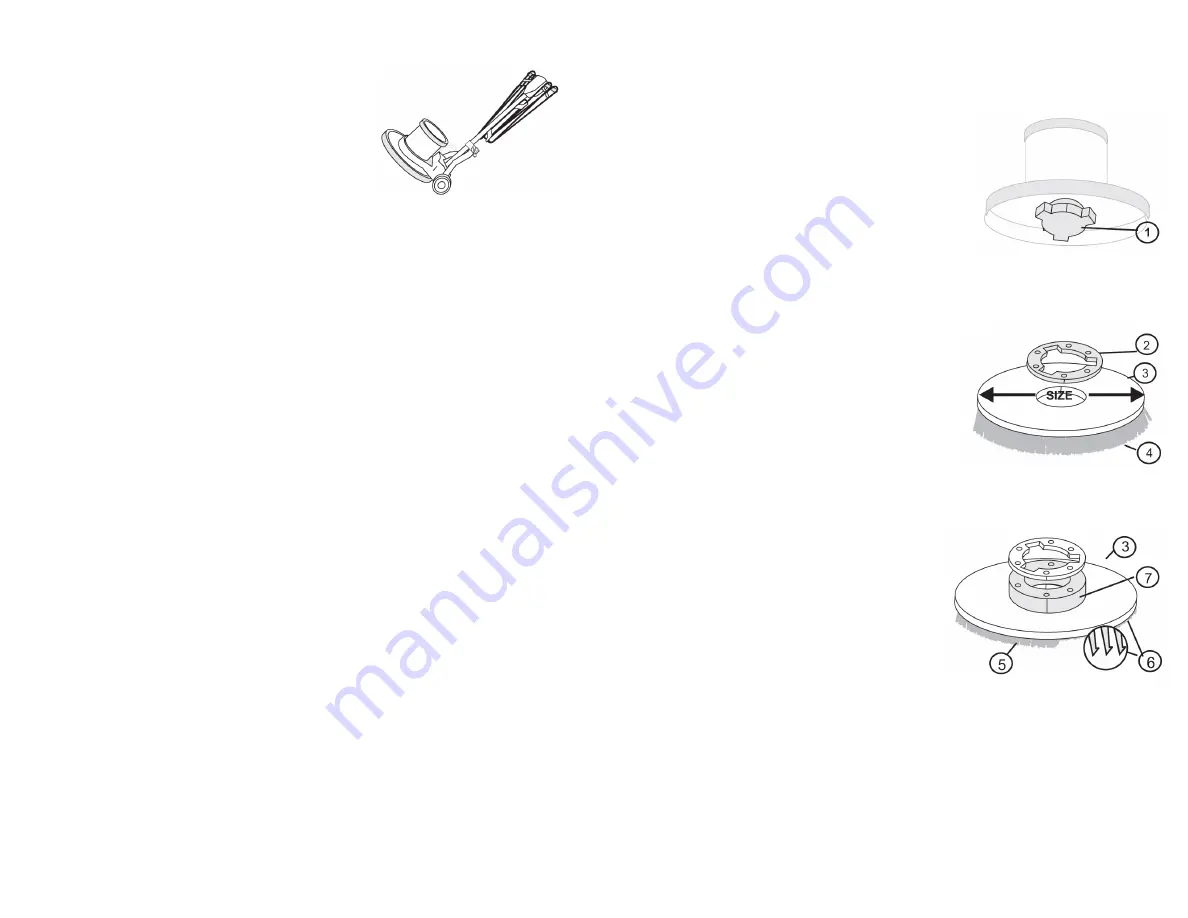

6.0 Brush Construction

Your new floor machine provides reliable, efficient,

safe power to your scrubbing brush. To get the best

results, you need to use a brush of the best design and

construction.

Your floor machine is built with a “B” style drive

plug (1). The height and width of the ears on the plug

will match a “B” style or “Universal” clutch plate (2)

mounted on the brush block.

The brush block (3) is constructed of molded plastic

or this plywood. Use a brush with a block diameter 2”

less than your machine apron size.

The bristle material (4) that actually does the

scrubbing is typically 1-1/2” to 2” long. Holes are

drilled in the block and bundles of bristles are folded

in half, forced into the hole and stapled in place

(staple-set).

When the bristles wear down to less than 1/2” long,

they have little flexibility and it’s time to replace.

Bristle materials are described on page 11.

6.1 Pad Driver Construction

If you scrub or polish with a non-woven pad, use a

pad driver to connect the pad to the machine.

The brush block (3) is constructed of molded plastic,

fit with shorter, stiffer, pad-holding bristles (5) or

“velcro-like” pad-holding hooks (6) and use a riser

(7) to create extra clearance between the block and

the machine apron. With this construction, use a pad

driver with block diameter 1” less than your machine

apron size.

Machine Apron Size

17” 19” 21”

Pad Driver - with 3/4” Riser

16” 18” 19”

Brush - with NO RISER

15” 17” 18”