33

Cutter Mode

Enable the label cutter mode.

Cutter Batch

Cut the label once at the end of the printing job.

Note: If printing from enclosed software/driver, the software/driver will send

out the command, which will overwrite the setting set from the front

panel.

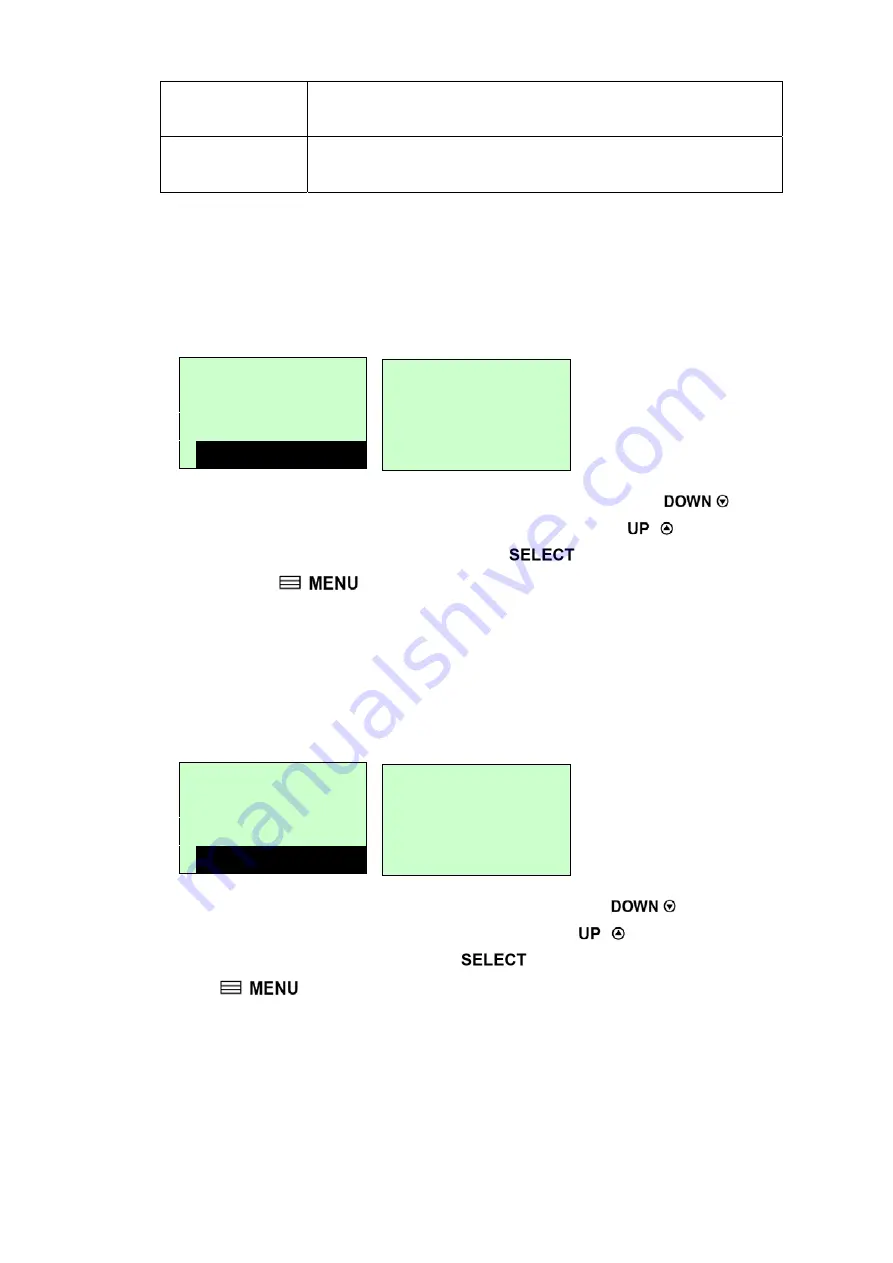

3.1.1.5 Offset:

This option is used to fine tune media stop location. Press the

button to

move the cursor from left digit to right digit, and press the

button to set the

value from “+” to “-” or “0” to “9”. Press the

button to set the value into

printer. Press

key to cancel the setting and return to the previous menu.

The default value is +000.

Note: If printing from enclosed software/driver, the software/driver will send

out the OFFSET command, which will overwrite the setting set from

the front panel.

3.1.1.6 Shift X & Shift Y:

This option is used to fine tune print position. Press the

button to move

the cursor from left digit to right digit, and press the

button to set the value

from “+” to “-” or “0” to “9”. Press the

button to set the value into printer.

Press

key to cancel the setting and return to the previous menu. The

default value is +000.

Note: If printing from enclosed software/driver, the software/driver will send

out the SHIFT command, which will overwrite the setting set from the

front panel.

3.1.1.6 Reference X & Reference Y:

Print Setup 5/12

Direction

Print Mode

>

Offset

Offset

+000

Print Setup 7/12

Offset

Shift X

>

Shift Y

Shift Y

+000

Summary of Contents for BP-8410M

Page 1: ...USER S MANUAL THERMAL TRANSFER DIRECT THERMAL BAR CODE PRINTER BP 8410M BP 846M BP 8463M...

Page 15: ...12 Loading path for ribbon...

Page 21: ...18...

Page 82: ...79...