15

LARGE CONTROL PANEL

The larger FAST® control panels are provided with box-lid enclosures. The face of the enclosure features

model and serial numbers, power indicator lamp, alarm indicator lamp, alarm silence button, and blower

switch. The electrical details of the control panel are printed on a label affixed to the outside of the enclosure.

The inside of the control panel enclosure contains a printed circuit board, and a contactor and overload rated

for the blower motor horsepower, voltage, and phase.

Some panels will also contain a transformer mounted next to the contactor. Terminations for incoming and

outgoing power are made in the field between the circuit board,

contactor and overload, and blower, based on the electrical diagram

supplied for each panel specifically.

Note:

The overload amperage setting supplied for a

given motor size is pre-set to the appropriate place at

the factory and does not need field adjustment.

If an overload trips when energized, make sure to double-check all

connections and electrical details for the control panel, blower, and

facility power supply.

The circuit board has two sets of normally open dry contacts for optional

connections such as a float switch or pressure switch. The normally

open contacts will activate the panel alarm when closed. Next to these

contacts are a 12VDC terminal that can be used to power an external

dialer device, and an alarm output terminal that can be used to signal an

external device when the panel goes into alarm. The alarm output is a

normally open switch that will close during an alarm condition

.

LARGE CONTROL PANEL

Summary of Contents for HighStrengthFAST 4.5

Page 2: ...1...

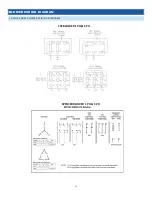

Page 15: ...12 FUJI BLOWER 1 PH FUJI BLOWER 3 PH...

Page 16: ...13 GAST BLOWER 1 PH...

Page 19: ...16 3PH 208V 240V 1PH 208V 240V 3PH 460V...

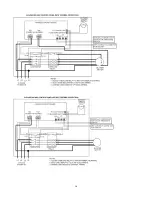

Page 20: ...17 CONTROL PANEL SCHEMATICS...

Page 21: ...18...

Page 22: ...19...

Page 23: ...20...