EN

a.

a.

b.

b.

c.

c.

d.

d.

a.

a.

b.

b.

a.

a.

b.

b.

a.

a.

b.

b.

a.

a.

b.

b.

a.

a.

b.

b.

a.

a.

b.

b.

c.

c.

a.

a.

b.

b.

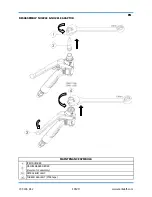

Check trigger setting / needle.

Replace gun handle and trigger lock.

Trigger lock worn.

Material leaks from

the outside of the

fluid nozzle adaptor.

Nozzle adaptor installed incorrectly /

loose.

Check nozzle adaptor assembly

installation / tighten.

Gun spits when

triggered.

Replace needle packing.

Check needle packing installation /

tighten.

POSSIBLE CAUSE

Material continually

flows from the nozzle.

Fluid pressure set too low.

Fluid passageways blocked.

Gun incorrectly adjusted.

Increase material pumping pressure.

Remove blockage from fluid

passageways.

Contamination preventing needle

from seating correctly.

Replace spring.

Thoroughly clean gun through, replace

material if necesarry.

FAULT FINDING

No matrerial flows

when gun triggered.

Change material.

Material contaminated.

Replace nozzle adaptor and needle.

Check trigger travel adjustment.

REMEDY

Swivel assembly worn.

Check swivel assembly installation /

tighten.

Replace swivel assembly.

Needle packing worn.

Needle packing assembly installed

incorrectly / loose.

Needle spring broken.

Damage to needle ball and or seat.

Trigger travel is incorrectly adjusted.

Nozzle adaptor or gun body

damaged.

Replace nozzle adaptor or complete flow

gun assembly.

Air in the system.

Continually trigger gun until all air is

removed from the system or check

supply system.

SYMPTOM

Material flows from

the end cap.

Swivel leaking.

Check fluid tube installation / tighten.

Fluid tube installed incorrectly /

loose.

Swivel assembly installed incorrectly /

loose.

Trigger lock won't

engage.

Replace trigger.

Trigger damaged.

Fluid tube or gun body damaged.

Replace fluid tube or complete flow gun

assembly.

Material flows down

the outside of the

fluid tube.

77-3246 R1.2

15/20

www.carlisleft.com