6

spray tecHnIQue for your Binks cub sl HVlp spray gun

spray tecHnIQue

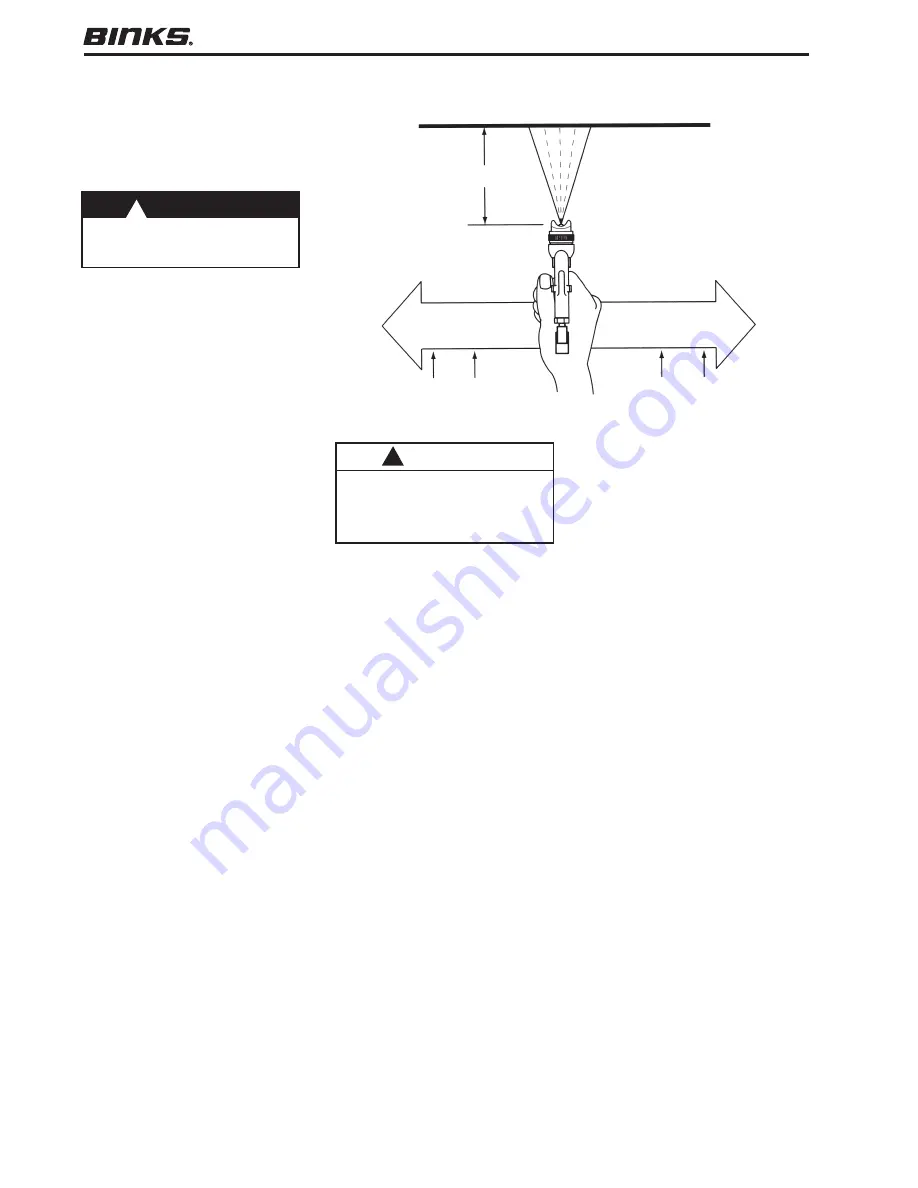

To get a good finish you must handle

the gun properly. Hold the gun per-

pendicular to the surface you are

painting. Make each paint stroke par-

allel to the plane of the surface being

painted. Start the stroke before you

trigger the gun and release the trigger

before you end the stroke. This will

give you accurate control of both gun

and material and prevent excessive

build-up of material at the stroke ends.

The distance between the gun and

surface should be 6"-10" depending

on the material and the atomizing

pressure. The material deposited

should always be even and wet. Lap

each stroke about half of the preced-

ing stroke to obtain a uniform finish.

If you HaVe trouBle

wItH gun operatIon

or resultIng fInIsH

faulty spray pattern

A faulty spray pattern is often caused

by dried materials around the fluid

nozzle tip or in the air nozzle left

behind by improper cleaning. Soak

these parts in thinner to soften the

material and remove it with brush

or cloth.

IntermIttent spray

Fluttering spray is caused by one

of the following problems:

1. The nut that attaches the fluid cup

may be loose. The packing nut

(28) may be loose. The packing

(29) may be worn and need

replacement. The fluid nozzle (35)

may be loose.

2. Insufficient fluid available.

Refill the cup.

spIttIng

Spitting is caused by anything that

restricts the movement of the fluid

needle assembly (10). The probable

causes are:

1. The packing nut (28) is too tight.

2. The fluid needle (13) is bent. You

may be able to straighten it.

Otherwise, it must be replaced.

3. Dried material has built up on the

needle or in the fluid nozzle (35).

4. Lumps or impurities in the fluid.

Strain the fluid.

6"-10"

spray tecHnIQue

CauTion

never use anything metal to clean

the air nozzle. these parts are pre-

cisely machined, and any damage

to them will cause faulty spray

patterns.

!

Warning

always wear appropriate gloves, eye

protection and a respirator when

using your gun.

!

start

stroke

trigger

gun

end

stroke

release

trigger