77-3046-R2.2 (9/2014)

9 / 16

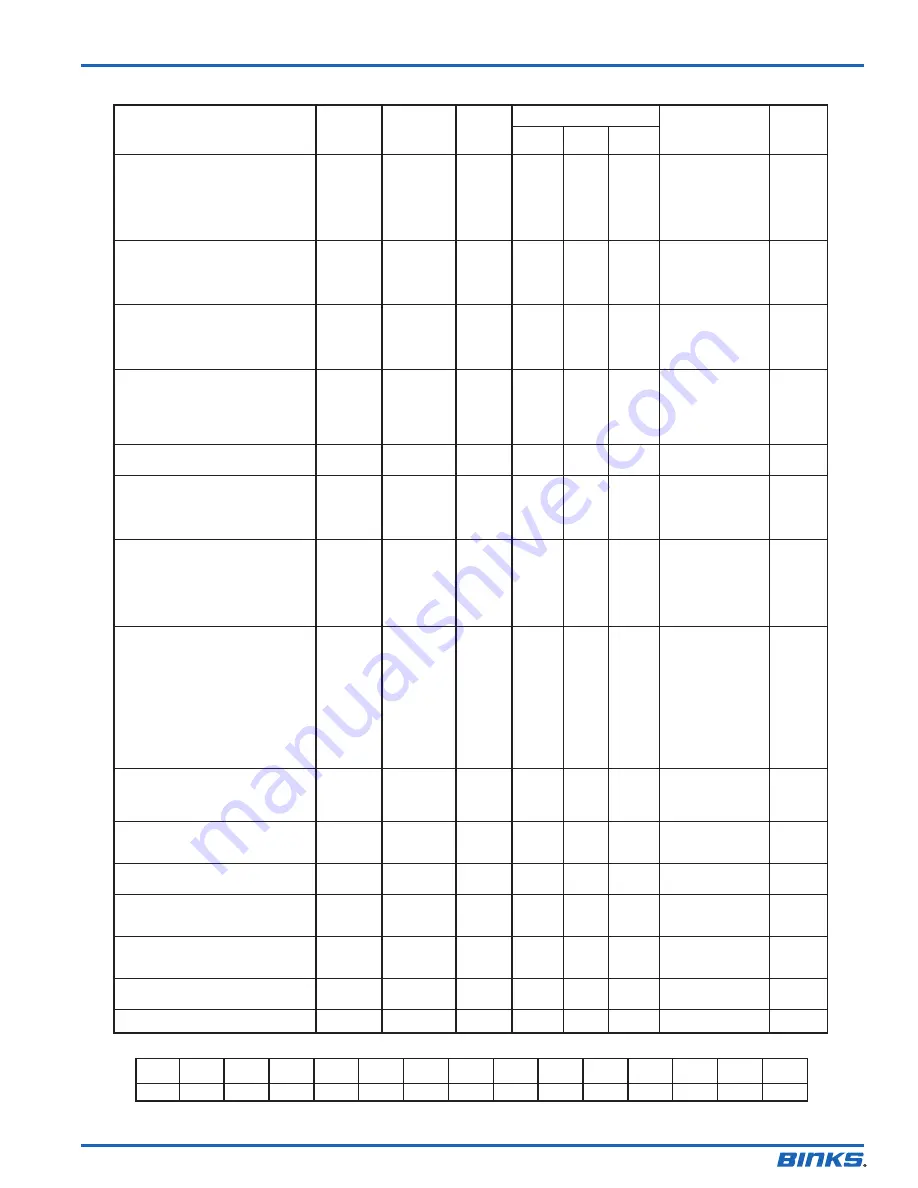

All air nozzles shown in combination with these (+) fluid nozzles can also be used in combination with any other fluid nozzle marked (+)

*See text Section B, page 8, for type code.

★

All standard needles listed are stainless steel.

FLUID NOZZLE ORIFICE SIZES

+

+

+

+ +

59ASS 59BSS 59CSS 63SS 63ASS 63BSS 63CSS

63CVT 64VT 65SS 66SS 67SS 67VT 68SS 68VT

.171 .218 .281 .028 .040 .046 .052 .052 .064 .059 .070 .086 .086 .110 .110

63SS

63P

PE

4.5 7.5 10.0

5.0

563

63ASS

63P

PE

5.1

8.7 12.2

11.0

563A

63BSS

63PB

PE

9.0 14.3 20.0

14.0

563A

66SS

66S

SE

3.4

5.0

9.0

565

66SS

66SD

SE

7.9 12.1

10.5

565

66SS

66SK

SE

11.0 15.2 19.5

13.0

565

63BSS

200

PI

3.1

5.2

6.4

12.0

563A

66SS

21MD-1 SE 12.0 17.3 23.0

11.0

565

66SS

21MD-2 SE 15.2 22.2 29.6

11.0

565

67SS

21MD-2

SE

12.5 18.3 24.4

13.0

567

63BSS

21MD-3

PE

11.6 16.6 22.2

16.0

563A

63ASS

63P

PE

5.1 8.7 12.2

11.0

563A

66SS

66SK

SE

11.0 15.2 19.5

13.0

565

63BSS

200

PI

3.1

5.2

6.4

12.0

563A

63CSS

PI

3.9

5.5

7.4

9.0

563A

63BSS

63PB

PE

9.0 14.3 20.0

14.0

563A

63CSS

63PR

PE

9.5 15.5 19.5

18.0

563A

66SS

66SD

SE

7.9 12.0

11.0

565

66SS

66SK

SE

11.0

15.2

19.5

13.0

565

63CSS

200

PI

3.1

5.2

6.4

12.0

563A

66SS

PI

3.9

5.5

7.4

9.0

565

65SS

63PR

PE

9.5 15.5 19.5

18.0

565

67SS

67PB

PE

9.5 14.9 19.5

12.0

567

68SS

68PB

PE

9.5

14.1

19.1

12.0

568

68SS

68PB

PE

9.5 14.1 19.1

12.0

568

59ASS

244

PI

7.8

11.5

15.2

12.0

559

59BSS

250

PI

7.3

11.0

14.7

RD

559

59BSS

252

PI

7.8

11.5

15.2

6.0

559

59CSS

262

PI

7.3

11.0

14.7

6.0

559

63CSS

63PB

PE

9.0 14.3 20.0

14.0

563A

66SS

63PR

PE

9.5

15.5

19.5

15.0

565

67SS

67PB

PE

9.5

14.1

19.1

12.0

567

63SS

66SD-3

PE

10.4 15.4 20.4

9.0

563

63ASS

66SD-3

PE

10.4

15.4

20.4

9.0

563A

63BSS

66SD-3

PE

10.4

15.4

20.4

11.0

563A

66SS

66SD-3

PE

14.2

21.2

28.3

10.0

565

66SS

66SDJG

PE

10.4

8.0-9.0

565

66SS

66R

PE/SE

4.2

RD

565

66SS

66SDJG

PE

10.4

8.0-9.0

565

L6SS

63PH-1

PE

9.5

14.2

19.0

18.0

565

63CVT

66PH

PE 11.5 16.4 22.0

13.0

573CVT

64VT

64PA

PE 12.1 15.0 21.0

13.0

574VT

67VT

67PD

PE

10.0 15.0 20.0

15.0

577VT

68VT

68PB

PE

9.5 14.1 19.1

12.0

578VT

66SS

200

PI 3.1 5.2 6.4

15.0

565

66SS

200

PI 3.1 5.2

12.0

565

63ASS

63PB

PE

9.0 14.3 20.0

10.0

563A

63BSS

63PR

PE

9.5 15.5 19.5

15.0

563A

66SS

66SD

SE

7.9 12.1

7.0

565

63CSS

63PB

PE

9.0 14.3

14.0

563A

66SS

63PB

PE

9.0 14.3

14.0

565

66SS

66SD

SE

7.9 12.1

7.0

565

63CSS

63PB

PE

9.0 14.3 20.0

10.0

563A

66SS

63PB

PE

9.0 14.3 20.0

10.0

565

67VT

67PB

PE

9.5 14.1 19.1

12.0

577VT

NOZZLE SELECTION CHART

CFM AT

MAX.

TYPE OF FLUID

FLUID

AIR

TYPE

PAT. FLUID

TO BE SPRAYED

NOZZLE

NOZZLE

*

30

50

70

(inches) Needle

PSI

PSI

PSI

AT 8 in. No.

★

CONCRETE CURING COMPOUNDS

MULTICOLOR PAINTS

NON-STICK COATINGS

HAMMERS

WRINKLE ENAMELS

ZINC RICH COATINGS

VERY THIN

14–16 Sec.—No. 2 Zahn

Wash Primers, Dyes, Stains, Solvents,

Water, Inks

VERY THIN TO MEDIUM

14–30 Secs. — No. 2 Zahn

NOTE: 21MD-1 AND 21MD-2 AIR CAPS CAN

SPRAY WITH PRESSURE SET-UPS PRODUCING

SPRAY PATTERS APPROX. 12” WIDE.

THIN

16–20 Secs. — No. 2 Zahn

Sealers, Primers, Lacquers, Inks,

Lubricants, Zinc Chromates, Acrylics

MEDIUM

19–30 Secs. — No. 2 Zahn

Lacquers, Syn. Enamels, Varnishes,

Shellacs, Fillers, Primers, Epoxies,

Urethanes, Lubricants, Wax Emulsions

HIGH SOLIDS

Enamels

HEAVY (CREAM-LIKE)

Over 28 Secs. — No. 4 Ford

House Paint, Wall Paint (Oil, Latex),

Block Sealers, Mill Whites, Vinyls, Acrylics,

Epoxies, Gel Coats

VERY HEAVY

Unaggregated, Block Fillers,

Textured Coatings, Fire Retardants,

Road Marking Paint, Bitumastics,

Cellular Plastisols, Underbody,

Roof Coatings

ADHESIVES

Waterbase —

White Vinyl Glue

Solvent Base —

Neoprenes

(Contact Cements)

CERAMICS &

SIMILAR ABRASIVE MATERIALS

Glazes, Engobes, Porcelain Enamel

Summary of Contents for 2100 SERIES

Page 14: ...77 3046 R2 2 9 2014 14 16 NOTES ...