Caution

Before installing a cutting tool, always use, on the internal diameter of the chuck, the internal and

external surfaces of the collet and on the shank of the cutting tool, kerosene or other degreasing

agents and wipe the dirty parts with a cloth.

Warning

The Air Turbine Spindle rotates at very high speed. In case of using cutting tools with a big

unbalance or tools with small diameter and long overhang, due to the centrifugal force, the

cutting tool may break creating an extremely dangerous situation. Use a cutting tool with high

rigidity and make it short as much as possible.

SPECIFICATIONS

UTILIZATION PROCEDURES

Clamping range (mm)

Tool diameter (mm)

Minimum spindle speed (min

-1

)

Maximum spindle speed (min

-1

)

Collet

ø0.45 - 4.05

ø1.5 or smaller

About 40,000 (0.3MPa)

About 50,000 (0.6MPa)

NBC4S-dAA (Option)

ø0.45 - 4.05

ø1.5 or smaller

About 60,000 (0.3MPa)

About 80,000 (0.6MPa)

NBC4S-dAA (Option)

Type

RBX5 / RBX5C

RBX7 / RBX7C

BIG-PLUS is a standard product of BIG Daishowa Seiki. Use machine tools with the

BIG-PLUS trademark to obtain a correct double face contact. BIG-PLUS holders are

also compatible with spindles of standard machines. In this case, check that there

are not projecting objects in the machine spindle’s surface and in the holder’s surface.

How to install / remove a cutting tool

1

Specifications

1

About BIG-PLUS (BBT, BDV, and BCV)

Use the X-Wrench and the Mega Wrench for install/remove the cutting tool. Please consult P4 “How

to use the X-Wrench” regarding how to use the X-Wrench.

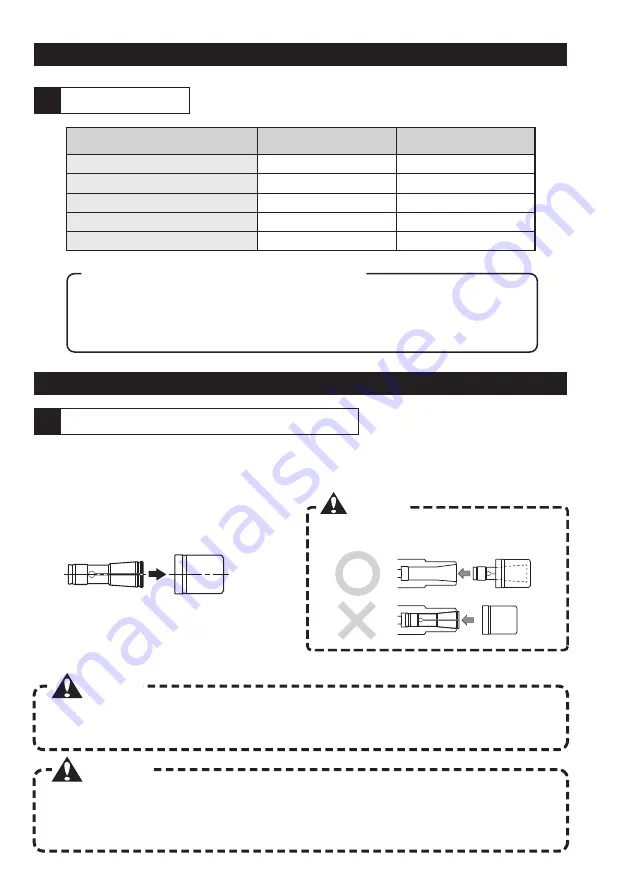

Always install the collet in the chuck body

after have inserted it into the nut.

Caution

Insert the collet from the rear part of the nut

and push it until the ribbed part of the collet is

set with a “click”.

It is possible to remove the collet from the nut

by pulling the collet straight along the spindle.

[Collet installation procedures]

[Collet removal procedures]

3