Maintenance

37

J

H

G

I

K

Fig. 8.6 (right side of the fan)

9 Disconnect the connector of the fan M by pres-

sing the plastic hook N placed on the rear side

of the connector (Fig. 8.7).

M

N

Fig. 8.7 (rear view of the fan)

If you notice dirt on the coil of the condensing heat

exchanger (19 on page 12) brush out it with a

bristle paintbrush and remove the dust with a

hoover.

Reassemble the parts carrying out the removal

operations in reverse order.

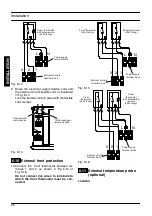

8.7

Checking the pressurisation

in the expansion vessel

Empty the central heating system as described in

section 8.4 of this chapter and check that the pres-

sure in the expansion vessel is not less than 1 bar.

See also section 4.6 page 18 of this manual.

If the pressure is lower, take steps to correct the

pressure level.

8.8

Cleaning the burner

The burner (38 on page 12) does not need special

maintenance, but it is sufficient to dust it with a

bristle paintbrush.

To reach the burner do the operations described

in the section 8.6 of this manual

8.9

Checking the flue

Have the integrity of the flue outlet pipe (47 on

page 13) air intake pipe (48 on page 13), checked

periodically, at least once a year.

For all the above maintenance operations it is ad-

visable to call an approved Service Engineer.

8.10

Drain pipe inspection

Check the soundness and integrity of the conden-

sate drain pipe.

Verify the cleanness and correct filling of the con-

densate traps.

8.11

Visual inspection of

appliance

Visually inspect all water joints, seals and connec-

tions for any evidence of leakage and retighten,

grease or replace them as necessary.

8.12

Gas pressures and soundness

Check appliance for gas soundness. Recheck op-

erational pressures as described in section 7.7

page 32 of this manual.

8.13

Water inhibitor concentration

Where chemical products are used the level of

water treatment should be checked on an annual

basis and re treated after full or partial drain down.

A conductivity meter can be used to check the cor-

rect concentration of inhibitor in the heating water.

M

A

INTE

NANC

E