20

11. OTHER AREAS OF POSSIBLE RISK

Type of malfunction

Possible origins of the problem

Solutions

No ram travel UP

- Oil level is too low

- Fill new oil in

No ram travel DOWN

- as above

- as above

Wedge moves slowly or will

not extend completely on nor-

mal log

- Oil level is too low

- Wrong valve détente

- Pump is broken

- Cylinder gaskets are damaged

- Fill oil in

- Adjust valve

- Replace pump

- Replace gaskets

Ram stops during splitting

- Log is too big, crogged or with lots

of branches

- Turn/adjust log position

Hydraulic hoses heat-up ex-

cessively

- Oil level is too low

- Pump is damaged

- Wrong valve détente

- Fill oil in

- Replace pump

- Adjust valve

The gasoline engine cannot

start

- Fuel is missing

- Fill up

12. TROUBLE SHOOTING CHART

11.1 Mechanical dangers

The special two-hands control mechanisms minimises risks and dan-

gers related to moving parts on the machine (wedge). An additional

safety is provided on the machine in order to prevent working with

only one handle while the other one is being engaged (held down) by

some mechanical tool or system.

DO NOT EVER ATTEMPT to remove or by-pass the two-hands control!

Danger: operating the splitter without the safety two-hands control

will increase your risk of having your hands pinched during the split-

ting cycle. Do not remove any other safety and protection device from

the machine.

Warning: Splitting without due safety devices will void the warranty

and might result into serious injures to the operator or the other per-

son around the workplace. Keep hands and fingers clear at all times.

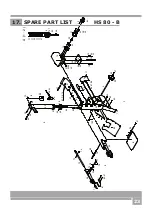

Summary of Contents for HS 80-2 B

Page 27: ...27...