BEST ACCESS SYSTEMS

Indianapolis, Indiana

lines up with the hub face (see Figure 40 — blow-up).

Note 1:

Make sure the locking pin locks into the rose liner.

Note 2:

Locksets will fit doors 1 3/4" to 2 1/4" thick. (A spacer is avail-

able for 1 3/8" doors.) See the enlarged view for the correct rose adjust-

ment for these thicknesses.

5

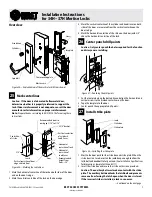

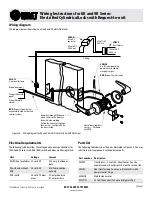

Engage retractor in latch

■

With the latch in place, install the chassis from the outside. Make

sure the latch tabs engage the chassis frame and the latch tailpiece

engages the retractor (see Figure 41).

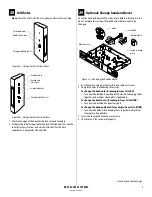

6

Install liner, through-bolts, rose and lever

Note:

For lead-lined locksets, slide the lead shield (not shown) over the

sleeve and into the 2 1/8" hole.

1 Align the holes in the liner with the holes prepared in the door.

2 Install through-bolts through the liner and door in the top and bot-

tom holes (see Figure 42).

3 Tighten the liner onto the door with the through-bolts.

4 Slide the rose over the sleeve, then press the rose onto the liner. The

rose should fit closely to the door surface.

5 With the lever pointing toward the hinges, push the lever on firmly

until seated.

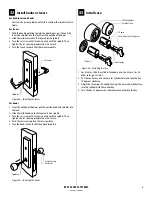

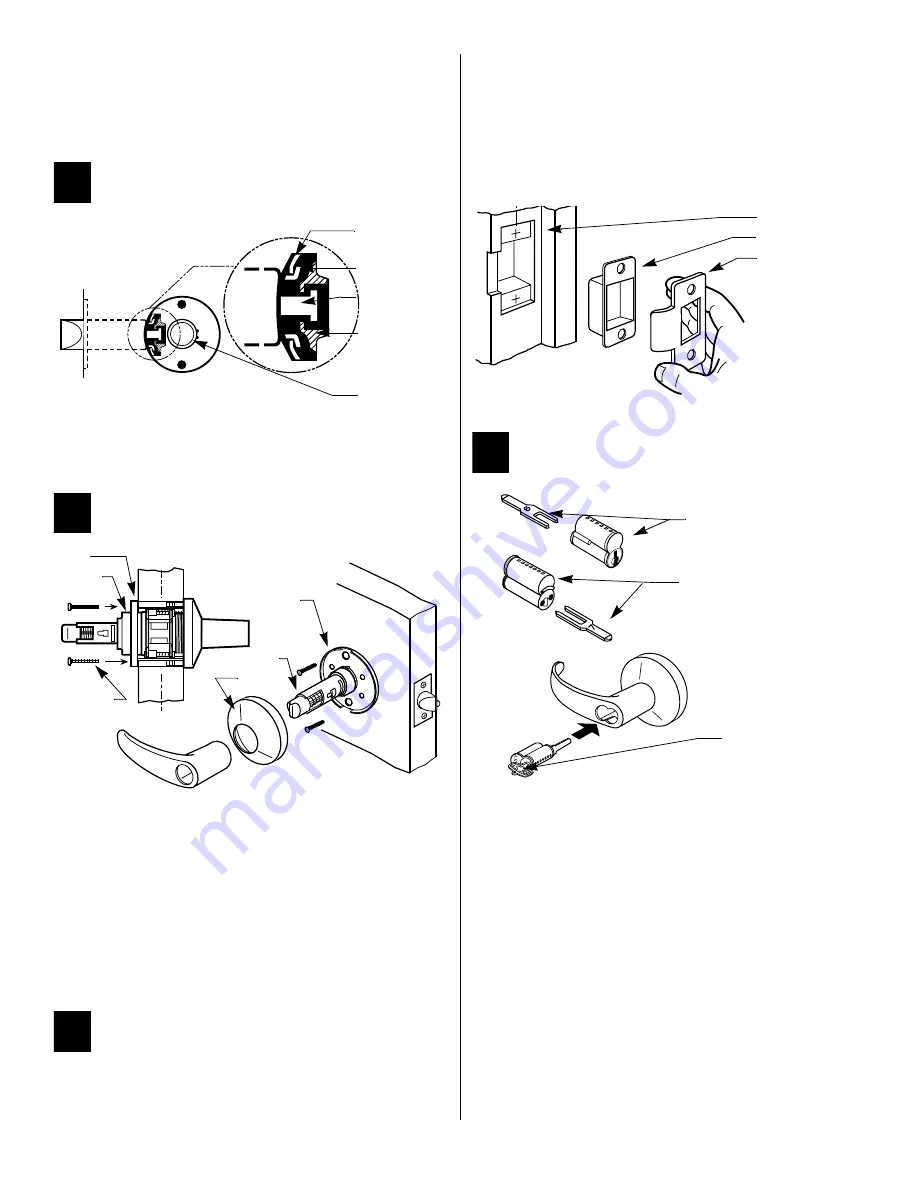

7

Install strike plate

1 In alignment with the center of the latch bolt, mortise the door jamb

to fit the strike box and strike plate.

Caution:

The deadlocking plunger of the latch bolt must not

enter the strike plate. The plunger deadlocks the latch bolt and

prevents forcing the latch when the door is closed. An exces-

sive gap may reduce security and/or cause a improper opera-

tion of the latch bolt assembly. A maximum door gap of 1/8" is

recommended.

2 Insert the strike box and secure the strike with screws provided (see

8

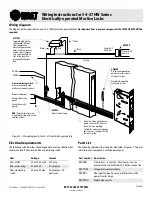

Install core

1 Insert the proper throw member into the core (see Figure 44 — top).

Six pin cores require the number “6” throw member; seven pin cores

require the number “7” throw member.

2 Put the control key into the core and turn the key 15 degrees clock-

wise.

3 Put the core and throw member into the lever with the control key

(see Figure 44 — bottom).

4 Turn the key 15 degrees counterclockwise and remove the key.

Caution:

Since the control key is a high-security key, make sure

to keep it protected.

Figure 41

Figure 42

Chassis frame

Latch tabs

Latch tailpiece

Retractor

Chassis

Chassis

Through

Inside liner

Sleeve

Rose

Liner

hub

-bolt

Figure 43

Figure 44

Door jamb

Strike box

Strike plate

BEST

6-pin core & throw member

7-pin core & throw member

Control key in core

T56075/Rev – 1798029 ER-7991-1 Jan 2000

Summary of Contents for 34HW

Page 1: ......

Page 6: ...Contents vi W Series Service Manual...

Page 38: ...IDH Max Locks Functions and Parts 2 24 W Series Service Manual...

Page 54: ...Electrified Locks Functions and Parts 3 16 W Series Service Manual...

Page 140: ...Service and Maintenance for Cylindrical Locks 5 30 W Series Service Manual...

Page 158: ...Additional Service and Maintenance for IDH Max Locks 6 18 W Series Service Manual...

Page 162: ...Glossary A 4 W Series Service Manual...

Page 164: ...Installation Instructions B 2 W Series Service Manual...