22

Major defects: A major defect is a defect that is likely to result in failure, or to reduce materially the usability of the

product for its intended purpose. Minor defects: A minor defect either is a defect that is not likely to reduce materially

the usability of the product for its intended purpose, or is a departure from an established having little bearing on the

effective use or operation of the product.

6.1 Electrical inspection specification

Inspection Item

Specification

1

Line defect

Can’t be seen.

2 Bright

dots

≤

2 dots (Note1, 4)

3 Dark

dots

≤

5 dots

4

Total dots defect

≤

5 dots

5

Adjacent dot defect

(Note 1, 2, 3)

Two continuous bright dots (vertical, horizontal, oblique):

≤

1 pair

Three or more continuous bright dots (vertical, horizontal, oblique):

Not allowed

Two continuous dark dots (vertical, horizontal, oblique):

≤

2 pair.

Three or more continuous dots – to be of any combination of dark dot

and bright dot (vertical, horizontal, oblique): Not allowed

Distance between 2 Bright dots:

≥

15 mm

Distance between 2 Dark dots:

≥

15 mm

Distance between Bright and Dark dots:

≥

15 mm

6

Display non-uniformity

Or Mura (Note 5,6)

Use 8% ND filter or judged by equivalent limit sample

Note 1:

For bright dot defect, bright area should be larger than 1/2 area of a sub-pixel to be count as 1 dot defect. A

dot defect that is smaller than the defined dot defect will be treated as small bright dot.

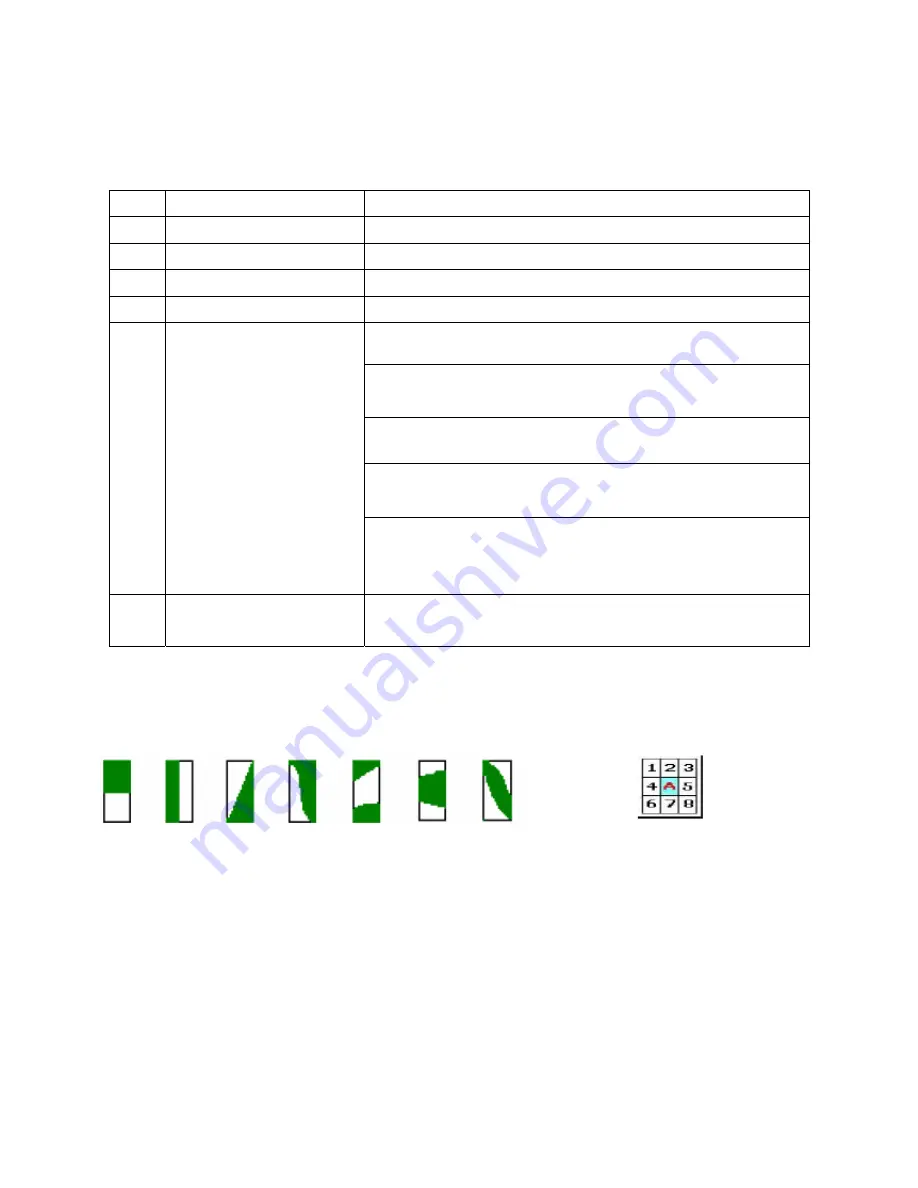

The drawing of 1/2 area sub-pixel definition: The 1/2 area sub-pixel can be defined as below one or more of specific

shapes (Fig.1).

Fig.1 Fig.2

All bright dot defects should not be noticeable by observer under specified inspection environment (Please refer to

item 5).

Note 2:

(Fig.2) Adjacent-dot defect (refer to picture, dot 1,2,..,8 around A are all A’s adjacent dots) should be

inspected under the same display pattern in any one of White /Black /Red /Green /Blue /Monotone Gray pattern.

Note 3: Adjacent-dot defect should be observed under any one of White /Black /Red /Green /Blue pattern. 1 pair of

bright dots equals 2 dots. Inspection patterns: Standard inspection patterns of dot defect are listed below. AUO uses

these patterns as standard criteria for judging dot defect. Please inform AUO if any other pattern is to be used to

examine dot defect.

Summary of Contents for G2450HM

Page 60: ...60 Six Angles View...

Page 70: ...70 9 Assemble the base...

Page 91: ...91 PCB LAYOUT Main Board 715G4997M0E000004L...

Page 92: ...92...

Page 93: ...93 Power Board GL2450HM GL2450HE 715G5000P01000003H...

Page 94: ...94...

Page 95: ...95 G2450HM 715G5000P01001003H...

Page 96: ...96...

Page 97: ...97...