10

11

1. General information

For an efficient operation of the sliding automatic mechanism, the gate must have the following features:

- The guide rail and its wheels must be suitable in size and mantained to prevent gate from excessive sliding

friction.

- When running, gate must not rock excessively.

- Opening and closing stroke must be regulated by a mechanical limit stop (to safety standard in force).

2. General features

Automation for intensive use sliding gates (max. gate weight 600kg).

The small and elegant design enbloc RI.624N consists of a painted aluminium unit containing the motor and

irreversible reduction unit, realized with high-grade materials.

The reduction parts are completely immersed in oil. The adjustment of the stroke is carried out automatically

by means of an encoder. The gate can be manually operated by a customized key release in the event of

power failure and wherever buffer batteries are not used.

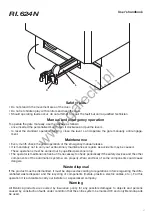

3. Foundation slab laying

Secure the foundation slab to the ground with no. 4 steel T pressure inserts to dimensions given in fig. 1 (it’s

important the slab is securely fastened to the ground).

N.B.: Go through holes F with a sheath suitable to the actuator feed cables.

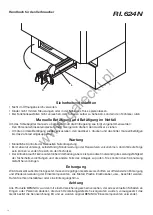

4. Rack fixing

4.1 Nylon rack (fig. 2)

Place the rack at a height of 125÷126 mm from the base of the foundation slab up to the rack tooth head;

drill and thread M6 the gate approx. in the center line between the rack slots. Now secure the rack and refer

to points 4.3 and 4.4 before proceeding.

4.2 Fe 12x30 mm rack (fig. 2)

Weld or screw the spacer pins D onto the gate at 144÷145 mm above the base of the foundation actuator

slab and maintain the same pitch as the rack drilling. Now secure the rack and refer to points 4.3 and 4.4

before proceeding.

4.3

Keep the pitch of teeth between the two parts of the rack; the joining with another piece of rack would

make it easier to achieve (see fig. 2)

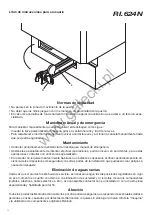

4.4

Secure the rack with the screws V making sure, once the actuator has been installed, that between rack

and the drive gear there is always approx. 1 mm clearance (see fig. 3); to get this clearance use the slots on

the rack.

5. Actuator positioning and fixing (see fig. 4)

Remove the case by untightening the screws V. Place the actuator unit so that the gear is centered to the

rack; level it with the grains G and if necessary adjust the clearance between rack and gears (according to

fig. 3). Now tighten the screws L.

6. Limit switch

The stroke adjustment is automatic and is carried out again after each manual operation (see instructions of

the control unit).

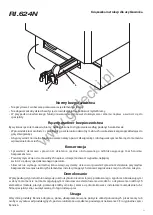

7. Manual operation

To operate the gate manually, use the release as follows (see fig. 5):

• Once inserted the personalized key C, turn it anticlockwise and pull the lever L.

• To reset the standard operation running, close the lever L and operate the gate manually, until engagement.

N.B.: After every manual operation, the automatic system carries out the stroke adjustment again (see in-

structions of the control unit).

8. Buffer batteries

If the system is to be used also in case of power failure, provide for 2 buffer batteries (12V-2.1Ah), housed and

connected as per fig. 6. With completely charged batteries, the autonomy for a door weighing 500kg and 5

metres long is of about 5 operations.

CAUTION

The civil liability policy, which covers possible injuries to people or accidents caused by defects in construction,

requires to use original Benincà accessories.

www.ga

ł

ecki.pl

Summary of Contents for RI.624N

Page 22: ...w w w g a ł e c k i p l ...

Page 23: ...w w w g a ł e c k i p l ...